Henan Tianzhong Vibration Equipment Co.Ltd

Client Request:

Henan Tianzhong Vibration Equipment Co.Ltd

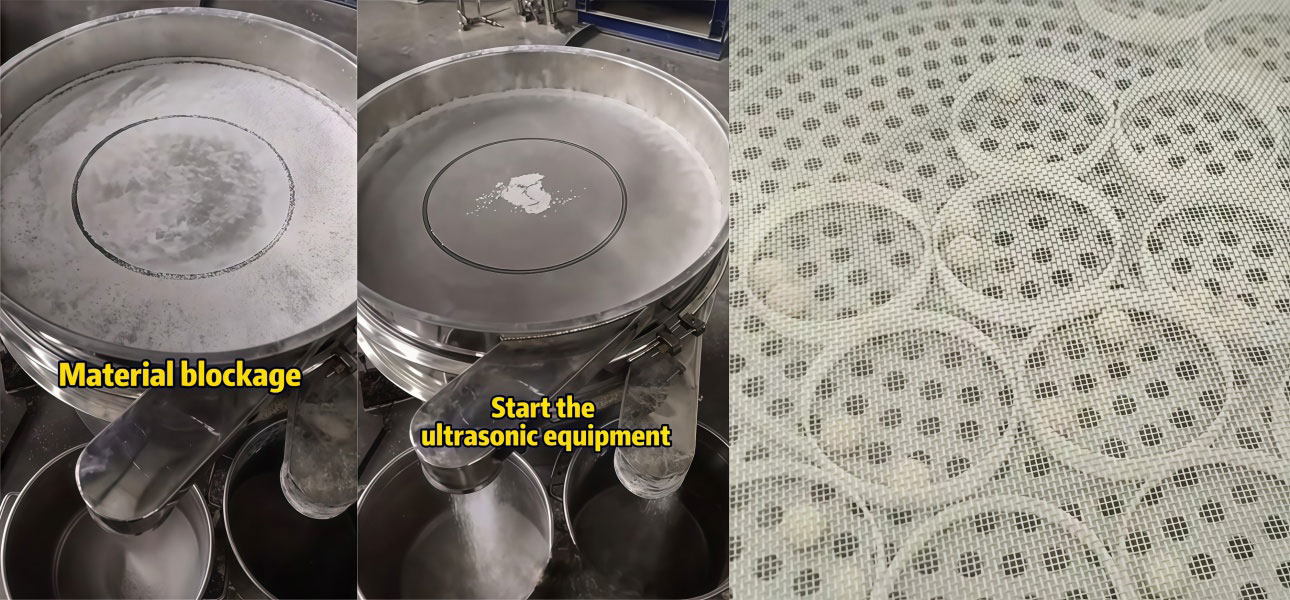

The Problem: A Malaysia-based processing plant faced severe production challenges. When handling moist, adhesive materials, their vibrating screen meshes blinded within minutes. Workers had to stop operations repeatedly for manual cleaning, leading to frequent downtime and extremely low screening efficiency. “Our workers were constantly tapping and cleaning the mesh, but output kept dropping,” the plant manager explained.

Our team diagnosed the core issues:

We implemented a targeted upgrade focused on overcoming adhesion at the mesh level:

After implementation, the client reported:

Contact us to learn how our international experience can benefit your operation!

Client Request:

Application:

Core Equipment:

Project Location:

Main Challenge:

Result:

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992