Henan Tianzhong Vibration Equipment Co.Ltd

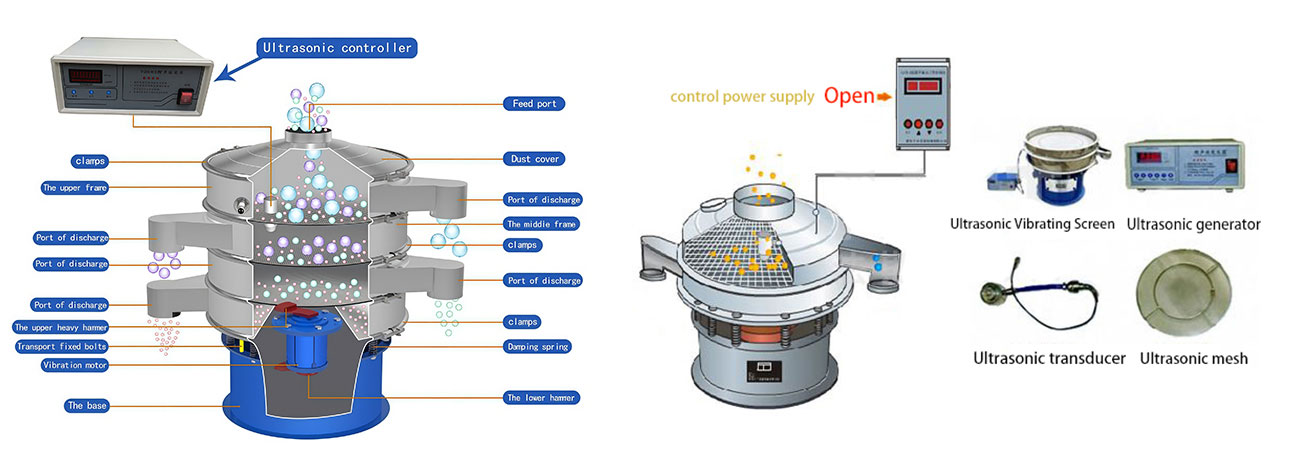

Ultrasonic Vibrating Screen

Achieving ultra-fine, high-precision screening with advanced ultrasonic anti-clogging technology.

Country of Origin: Henan, China

Technical Parameters:

-

Screen Diameter: 400–2000 mm (16–78 in)

-

Screen Mesh Size: 2-500 mesh or customized

-

Layers: 1-5 layers

-

Material: Stainless Steel 304 / 316L , Carbon steel

Get a Fast Quote from the Manufacturer

- Reply within 12 hours

- Free technical advice

- No spam, no obligation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

What is Ultrasonic Vibrating Screen?

The ultrasonic vibrating screen is an advanced sieving machine that integrates ultrasonic technology with high-frequency vibration to achieve ultra-fine and efficient particle separation. It is specially designed to handle difficult-to-screen materials, such as those with strong adhesion, static charges, lightweight properties, or tendencies to agglomerate.

Main Features

Performance Advantages

- Ultrasonic vibration prevents mesh clogging and boosts screening efficiency

- Achieves precise screening up to 600 mesh with stable and consistent output

- Improves powder flowability for higher throughput and finer separation

- Fully enclosed design ensures dust-free and clean operation

- Low noise, low energy consumption, and easy to clean or maintain

Custom Options

- Ultrasonic system: single-frequency, dual-frequency, or auto frequency tracking

- Explosion-proof motor and control box for hazardous environments

- 1–5 screen layers for multi-grade separation

- Seal materials: silicone, rubber, PTFE, or high-temperature types

- Custom inlet/outlet size, angle, and height to fit production layout

- Optional quick-release clamps for faster cleaning and mesh replacement

contact us to get your solution for free!

Applications

New Energy Materials

- LFP, ternary materials

- Lithium cobalt oxide, LNCM, graphite

- Battery-grade additives and fine powders

Chemicals Powders

- Spherical silica, fused silica, microsilica

- Resins, pigments, dyes, fillers

- Activated carbon, catalysts

Food & Pharmaceuticals

- Coffee powder, cocoa powder

- Starch, powdered sugar, food additives

- Chinese & Western medicine powders

Metal & Mineral Powders

- Copper, aluminum, iron, alloy powder

- Quartz sand, glass powder, alumina

- Abrasives: corundum, emery

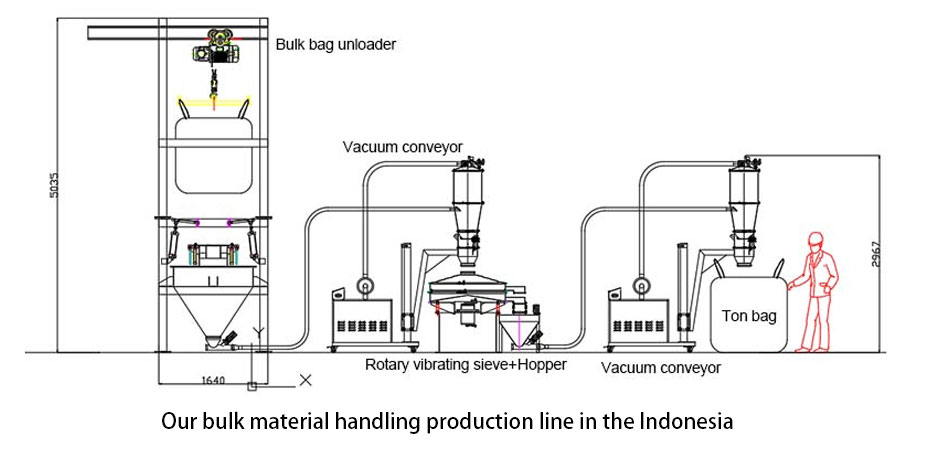

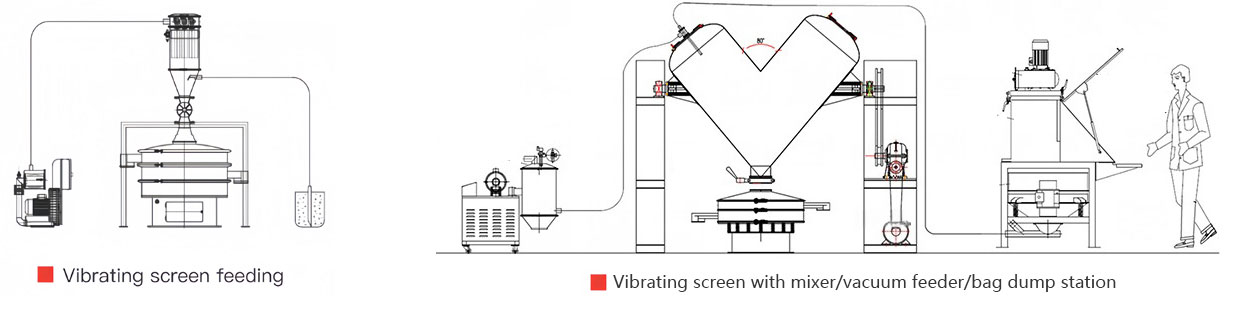

Explore Our Key Integration Examples

Our ultrasonic vibrating screens are expertly designed for a wide range of applications:

Technical Parameters

| Model | Parameter | Category | Parameter |

|---|---|---|---|

| Frequency | 35KHZD | Electrical system and dimension | 300mm*300mm*300mm |

| Power supply | 220V-240V 50/60HZ | Clamshell | IP65 |

| Working mode | Contact work style | Adjustment range | 50–100% |

| Maximum environmental temperature | -10–45°C | Resonator | Plug type |

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

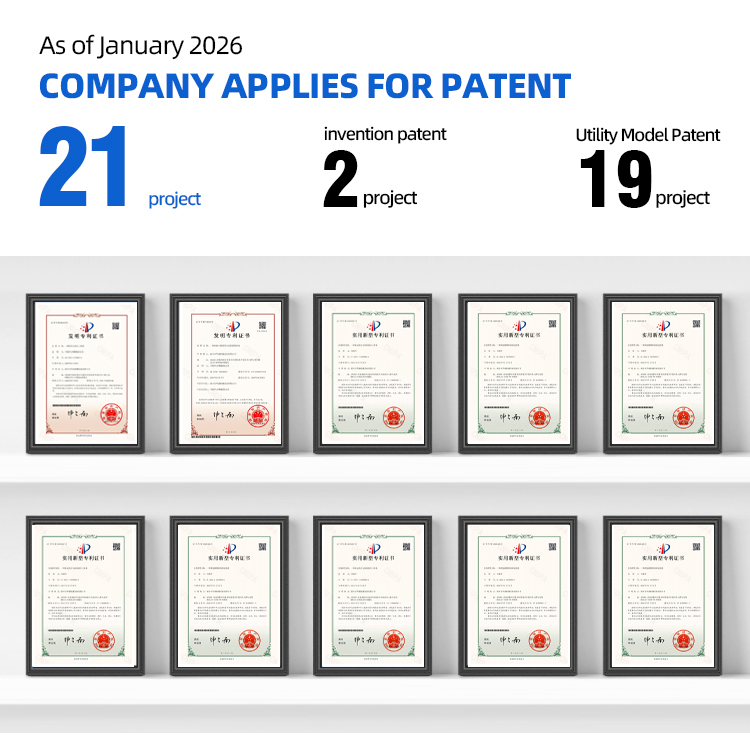

Company Strength