Henan Tianzhong Vibration Equipment Co.Ltd

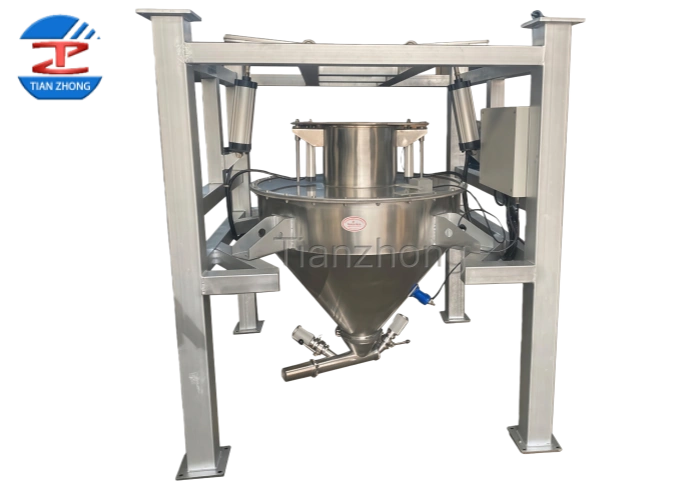

Bulk Bag Unloader

Improve plant hygiene and efficiency with safe, dust-free big bag unloading designed for smooth flow.

Country of Origin: Henan, China

Typical Specifications (Customizable):

-

Loading Capacity: ≤ 2tons or customized

-

Structure Dimension: Based on the request of clients

-

Bag Unpacking Ability: 10-30 bags/hour

-

Material: Stainless Steel , Carbon steel

Get a Fast Quote from the Manufacturer

- Reply within 12 hours

- Free technical advice

- No spam, no obligation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

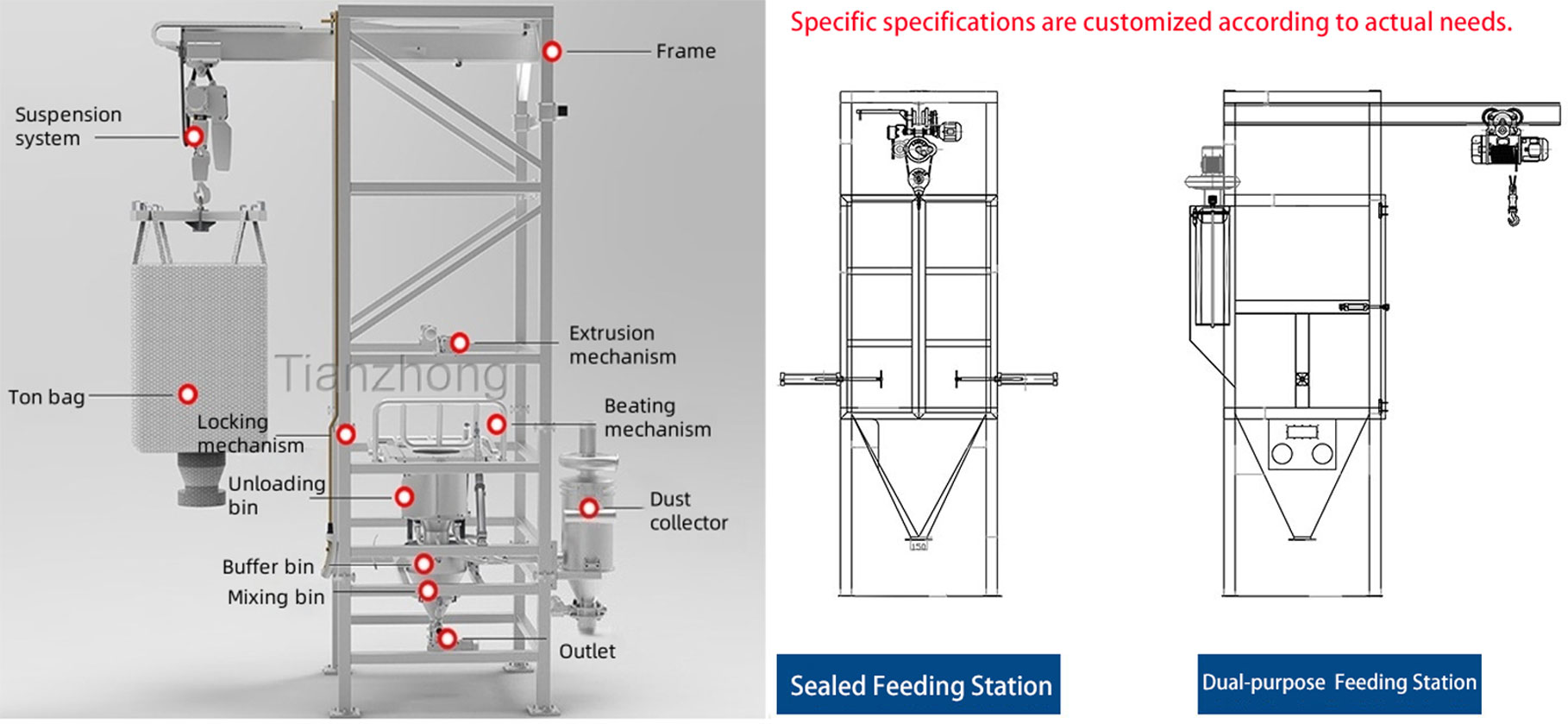

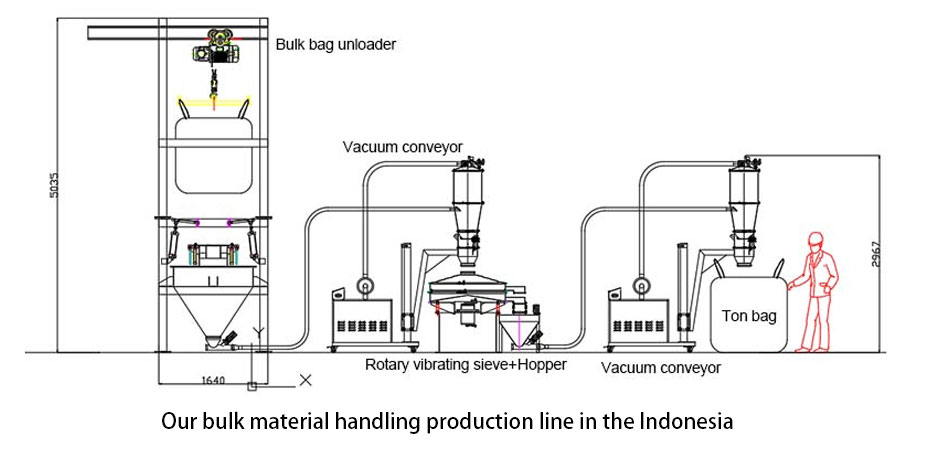

What is bulk bag unloader?

The Bulk bag unloader (bag-opening station) is an integrated system specifically designed for automated feeding of powdered materials. Through intelligent control and modular construction, it enables efficient bag-opening, dust suppression, and precise material transfer for bulk bags. This equipment is suitable for raw material processing in industries such as lithium batteries, chemicals, pharmaceuticals, and food. Its primary objective is to address the challenges of low efficiency, severe dust pollution, and high material residue rates associated with traditional manual bag-breaking methods, while meeting production demands for high cleanliness and safety. The discharge port of the ton-bag breaker can interface with equipment such as hoppers, screw conveyors, rotary discharge valves, crushers, electromagnetic separators, and vacuum loaders.

Main Features

Performance Advantages

- Gentle material handling with controlled vibration for complete bag emptying

- Fully enclosed design, zero dust leakage, in line with standards

- Processing speed up to 5-20 bags/hour, low material residual rate

- Compatible with materials with poor fluidity, easy agglomeration, and moisture absorption (such as graphite powder,LiFePO4, silica fume, etc.)

- Equipped with emergency stop button, safety door and other protective devices, supporting explosion-proof certification.

Custom Options

- Multiple discharge options: manual, pneumatic, or motorized valve control

- Customizable frame height and discharge height to match process requirements

- Various safety options: safety interlocks, pressure relief vents, bag tensioners

- Material contact parts available in carbon steel, stainless steel, or special coatings

- Optional accessories: bag compactor, platform, sieve, or pneumatic conveyor interface

contact us to get your solution for free!

Applications

Food & Pharmaceutical

- Milk powder, protein powders

- Flours, starch, sugar

- Vitamins, pharmaceutical powders

- Tea, spices, food additives

Chemicals & Plastics

- PVC, PE, PP plastic pellets

- Resins, polymers, compounds

- Catalysts, chemical powders

- Fertilizers, industrial chemicals

Minerals & Construction

- Cement, fly ash, limestone

- Sand, silica, clay powders

- Gypsum, plaster, dry mixes

- Ceramic powders, pigments

Recycling & Biomass

- Recycled plastic flakes

- Wood chips, biomass pellets

- Metal powders, recovered materials

- Activated carbon, filter media

Technical Parameters

| Model | Length*Width | Electric hoist specification | Dust removal fan power | A(mm) | B(mm) | C(mm) |

|---|---|---|---|---|---|---|

| HC800 | 800*800 | 1T | 1.1 | 2000 | 1530 | 3650 |

| HC1000 | 1000*1000 | 2T | 1.1 | 2270 | 1530 | 4200 |

| HC1400 | 1400*1400 | 2T | 1.1 | 2270 | 1930 | 4500 |

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

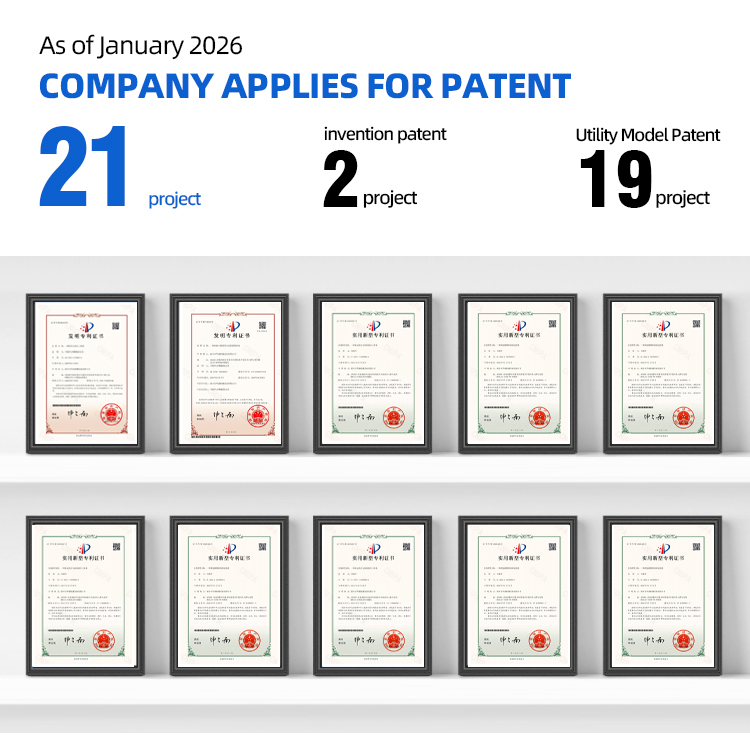

Company Strength