Henan Tianzhong Vibration Equipment Co.Ltd

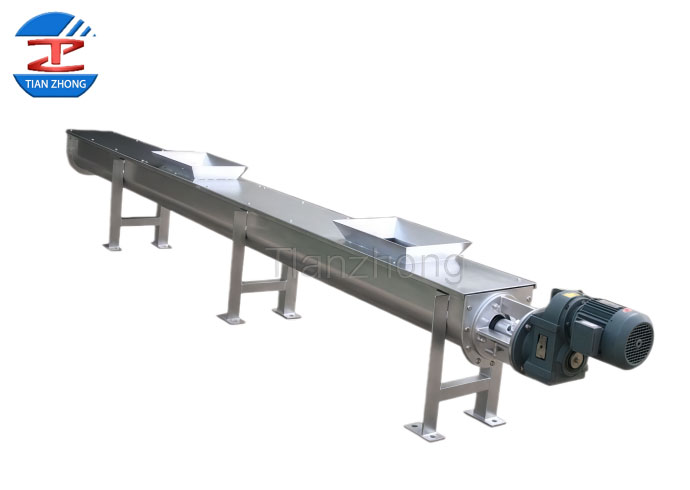

Screw Conveyor

Ensure steady, reliable conveying for powders and granules with a robust, low-maintenance screw design.

Country of Origin: Henan, China

Typical Specifications (Customizable):

-

Conveying length(m): Customized

-

Conveying height(m): Customized

-

Adjustable angle: ≤60 degrees or 90 degrees

-

Max capacity(t/h): Based on the need of clients

Get a Fast Quote from the Manufacturer

- Reply within 12 hours

- Free technical advice

- No spam, no obligation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

What is screw conveyor?

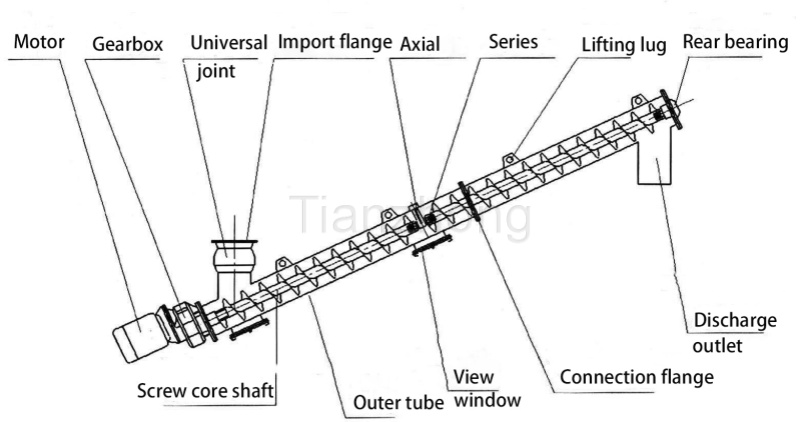

Screw conveyor is a kind of continuous conveying equipment widely used in metallurgy, building materials, chemical industry, grain and mechanical processing departments. It is mainly used for conveying all kinds of loose materials such as powder, granules and small blocks. This machine is not suitable for conveying special materials that are easy to deteriorate, sticky, caking or high temperature, afraid of pressure and corrosive. Screw conveyor can be divided into horizontal and inclined types according to the conveying angle.Based on the trough configuration, there are two types: U-shaped trough and pipe-type.

Screw conveyor generally consists of three main components: the conveyor body, the inlet and outlet ports, and the drive unit. The screw blades of screw conveyors come in three forms: solid screw surfaces, belt-type screw surfaces, and blade-type screw surfaces, among which the blade-type screw surface is relatively less commonly used. It is primarily employed for conveying materials with high viscosity and compressibility.

Main Features

Performance Advantages

- Compact cross-section design saves space while maintaining high conveying capacity

- Excellent sealing performance prevents material leakage and dust emission

- Stable and reliable operation with low maintenance requirements and long service life

- Flexible multiple feeding and discharge points along the conveyor length

- Safe operation with full enclosure and minimal moving parts exposure

Custom Options

- Various screw types: ribbon, cut-flight, hardened, or tapered designs

- Multiple material options: carbon steel, stainless steel, or special coatings

- Custom lengths and diameters to suit specific layout requirements

- Optional features: slide gates, hoppers, or multiple discharge outlets

- Flexible drive arrangements: direct drive, gear reducer, or shaft-mounted options

contact us to get your solution for free!

Applications

Food & Pharmaceuticals

- Sugar, starch, milk powder

- Rice flour, food additives

- Protein powder, granules

Chemicals & Plastics

- Resins, pellets

- Pigments, industrial compounds

Minerals & Building Materials

- Cement, lime, alumina

- Calcium carbonate, quartz sand

Metallurgy & Refractories

- Aluminum powder, ore powder

- Refractory materials, kaolin

Technical Parameters

| Screw Model | Screw Diameter (mm) D |

Pitch (mm) S |

Rotational speed (r/min) n |

Flow rate (m³/h) ψ=0.33 |

Rotational speed (r/min) n |

Flow rate (m³/h) ψ=0.33 |

Rotational speed (r/min) n |

Flow rate (m³/h) ψ=0.33 |

Rotational speed (r/min) n |

Flow rate (m³/h) ψ=0.33 |

|---|---|---|---|---|---|---|---|---|---|---|

| LS100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| LS125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 |

| LS160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 |

| LS200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 |

| LS250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| LS315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 |

| LS400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 |

| LS500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| LS630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 |

| LS800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 20 | 99.3 | |

| LS1000 | 1000 | 560 | 32 | 277.9 | 25 | 217.1 | 20 | 16 | 139.0 | |

| LS1250 | 1250 | 630 | 25 | 381.7 | 20 | 305.4 | 16 | 13 | 198.5 |

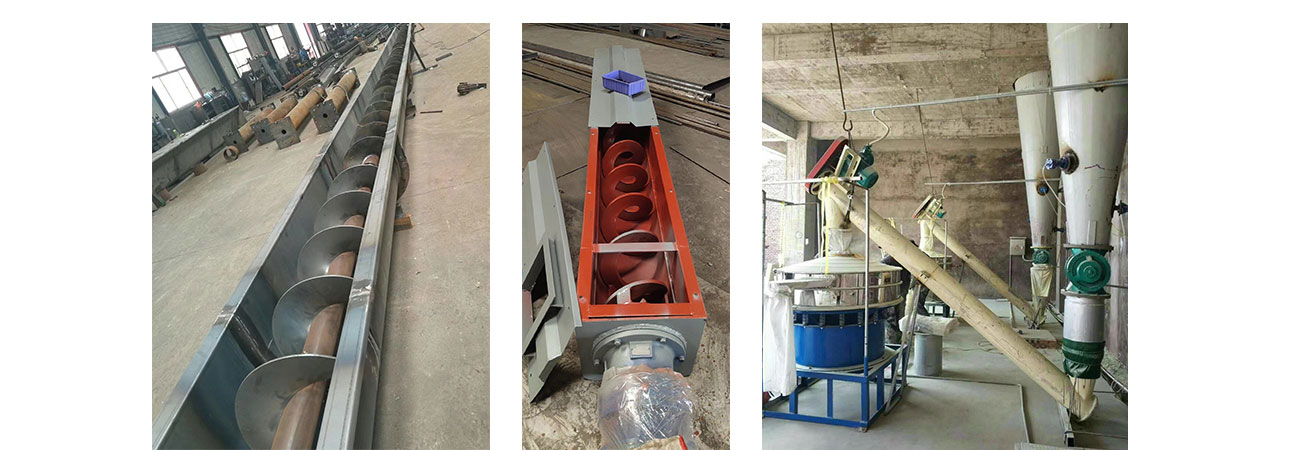

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

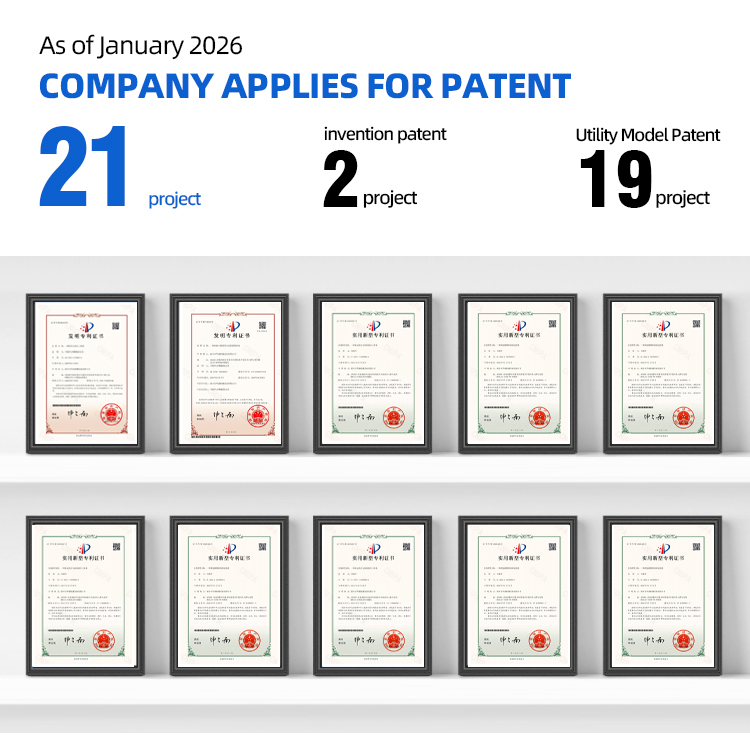

Company Strength