Henan Tianzhong Vibration Equipment Co.Ltd

Client Request:

Henan Tianzhong Vibration Equipment Co.Ltd

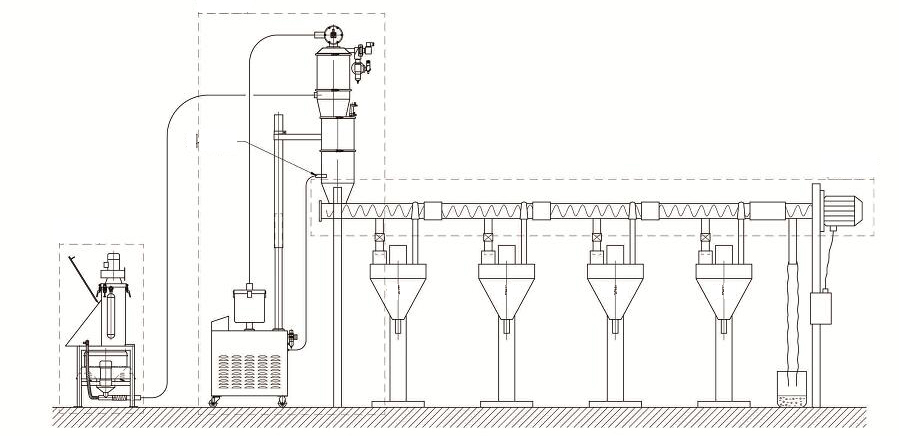

We recently commissioned a complete Vietnam Integrated Packaging Line for a leading food processing plant in Ho Chi Minh City. This turnkey system seamlessly connects vacuum conveying, automated packaging, and intelligent material handling through an integrated network, revolutionizing their spice and powder packaging operations.

Our integrated system combines multiple technologies into one efficient workflow:

The Vietnam Integrated Packaging Line operates through a sophisticated material handling sequence:

Material Intake: Operators safely empty raw material bags into the small bag dumping station, which features dust containment and ergonomic design for worker comfort.

Conveying Phase: The vacuum conveying system automatically transports materials from the dumping station to the packaging machines through sealed pipelines, eliminating manual handling and dust emission.

Packaging Process: Materials are precisely weighed and packaged by automatic packaging machines, with finished bags transferred via the conveyor belt system to the next production stage.

The complete Vietnam Integrated Packaging Line delivers multiple benefits:

The implementation of our Vietnam Integrated Packaging Line has transformed the client’s operations:

This project demonstrates our capability in delivering fully integrated Vietnam Integrated Packaging Line solutions that address the complete packaging process from material intake to finished product output.

Contact us today to discuss your integrated packaging line requirements!

Client Request:

Production Line:

Core Equipment:

Project Location:

Main Challenge:

Solution:

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992