Henan Tianzhong Vibration Equipment Co.Ltd

News Details

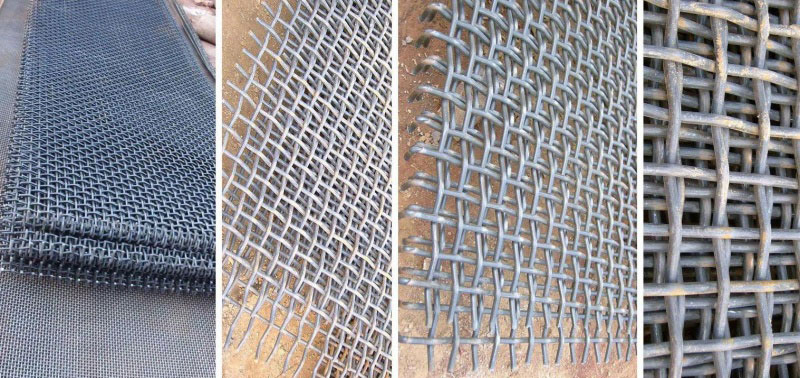

What is Mesh Size? Simply Put

In industrial sieving and filtration, mesh size is a critical number. It doesn’t measure the wire thickness of a screen. Instead, it counts the number of openings in a linear inch of that screen.

For example, a 100-mesh screen has approximately 100 openings per inch. The higher the mesh number, the smaller the openings, and the finer the particles it can sieve out.

Mesh Size vs. Particle Size

Mesh size directly correlates to the maximum particle size that can pass through. A particle must be smaller than the screen opening. Therefore, specifying a mesh size effectively defines the particle size cutoff. Common references use “mesh” to describe powder fineness (e.g., “200-mesh powder”).

Key Factors in Screen Specification

When choosing a screen, mesh size is just the start. Consider:

Wire Diameter:

Affects opening size and screen strength.

Aperture Size:

The actual distance between wires, determining the particle size cutoff.

Open Area:

The percentage of open space, impacting flow rate and efficiency.

The Bottom Line

Mesh size

is your starting point for

screen specification

. It’s a practical, if imperfect, system for linking particle size to the physical screen. For precision, always confirm the exact aperture size in microns or millimeters alongside the mesh count.

Understanding this concept ensures you select the right screen for effective separation, whether for powders, granules, or liquids.

If you have further questions, please contact us.

Related Posts

2026-01-30

Why use vacuum feeders for powder transportation?

In modern industrial production, especially in sectors like pharmaceuticals, food processing, and ch...

2026-01-14

How Does a Vacuum Conveyor Work?

Vacuum conveyors, also known as vacuum conveying systems or vacuum powder transfer systems, are esse...

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992