Henan Tianzhong Vibration Equipment Co.Ltd

News Details

How Does a Vacuum Conveyor Work?

Vacuum conveyors, also known as vacuum conveying systems or vacuum powder transfer systems, are essential for automated, dust-free handling of powders and granules. But how do they work? This article breaks down the simple yet efficient working principle of vacuum conveying into five key stages.

How Does a Vacuum Conveyor Work? The 5-Step Principle

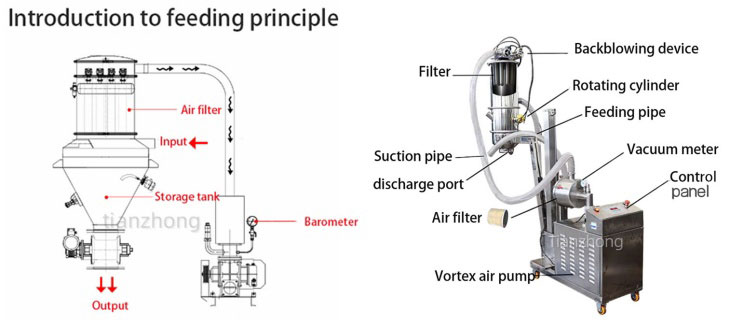

The system operates on a precise cycle of negative and positive pressure. The core working principle of vacuum conveying can be broken down into five key stages for efficient powder transfer.

1. Vacuum Generation & Suction: A vacuum pump or generator creates negative pressure inside the receiver vessel. This pressure difference forces air and material from the source (like a drum or hopper) through the suction line.

2. Filtration & Separation: The air-powder mixture enters the vessel and passes through a high-efficiency filter. The filter retains all conveyed material, separating it cleanly within the receiver while air passes through.

3. Material Discharge: Once full, the vacuum stops. A discharge valve at the vessel’s bottom opens, allowing the separated material to fall by gravity into the downstream process (e.g., a mixer or packer).

4. Filter Cleaning (Reverse Pulse): A key function for continuous operation. A short, powerful pulse of compressed air is blasted backwards through the filter. This filter cleaning process dislodges particles, maintaining suction efficiency.

5. System Reset: The discharge valve closes, and the system resets, ready to begin the next conveying cycle automatically.

Key Advantages of This System

The vacuum conveying system design offers significant benefits for modern production.

Fully Enclosed & Dust-Free: Protects both operators and product from contamination, ensuring a clean working environment.

Flexible Installation: Systems can be easily adapted to existing production lines, with components placed where needed.

Automated & Efficient: Enables rapid, hands-off transfer of materials, reducing labor costs and improving process reliability.

Gentle Material Handling: Suitable for a wide range of powders and granules without degradation.

Applications & Selection Considerations

Vacuum conveyors are versatile and used across many industries.

Wide Industry Use: Ideal for food, pharmaceutical, chemical, and plastic industries where hygienic or contained transfer is required.

Material Compatibility: System configuration (like pump type, filter material, and tube type) must be selected based on material properties such as density, flowability, and moisture.

Conclusion

Understanding the working principle of vacuum conveying highlights its role as a reliable and efficient method for automated powder handling. By leveraging a simple cycle of vacuum and pressure, these systems prevent dust, enhance safety, and streamline production. For optimal performance, proper selection based on material characteristics and process goals is essential.

Want to learn more Vacuum Conveyor Work? Contact Our Experts Today!

Related Posts

2026-01-30

Why use vacuum feeders for powder transportation?

In modern industrial production, especially in sectors like pharmaceuticals, food processing, and ch...

2026-01-14

How Does a Vacuum Conveyor Work?

Vacuum conveyors, also known as vacuum conveying systems or vacuum powder transfer systems, are esse...

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992