Henan Tianzhong Vibration Equipment Co.Ltd

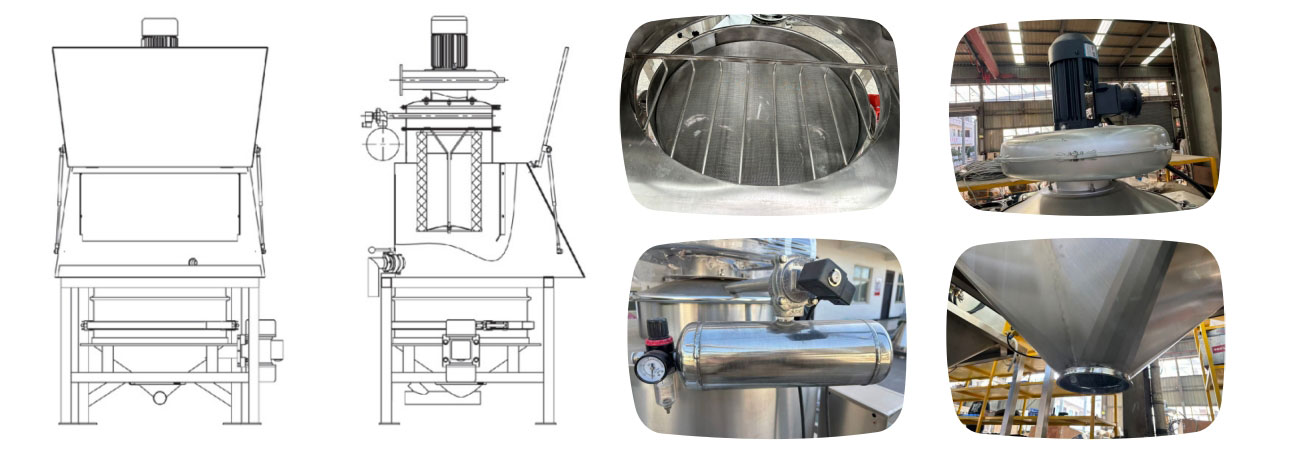

Bag Dump Station

Create a cleaner, safer workplace with controlled dust collection during manual bag dumping.

Country of Origin: Henan, China

Typical Specifications (Customizable):

-

Flow rate(kN): 997-1550

-

Size of Damping Station (mm): Customized

-

Bag Unpacking Ability: 10-30 bags/hour

-

Material: Stainless Steel , Carbon steel

Get a Fast Quote from the Manufacturer

- Reply within 12 hours

- Free technical advice

- No spam, no obligation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

What is bulk bag unloader?

Bag dump station (Small bag dust-free feeding station) is a kind of automated equipment for handling powder and granular materials, aiming at realizing dust-free and airtight feeding process, which is widely used in chemical, pharmaceutical, food and other industries.

Main Features

Performance Advantages

- Dust-free operation: Effectively prevent dust from flying, protect the environment and health of operators

- The equipment is designed to be airtight, reducing material waste and environmental pollution

- Simple structure, easy to operate, easy to maintain and clean.

- Can be customized according to user requirements to meet different production needs

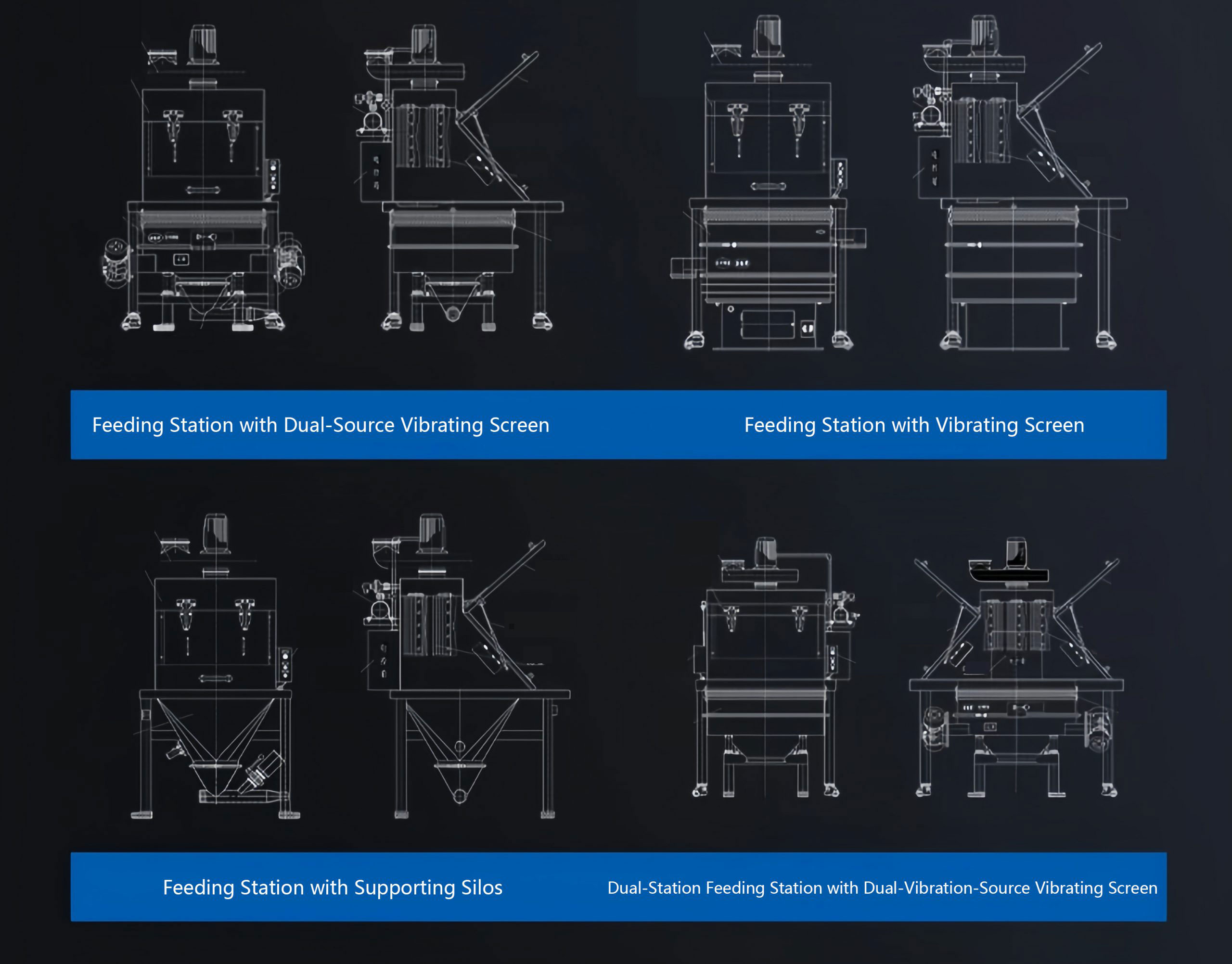

Custom Options

- Multiple material options: 304 stainless steel, 316 stainless steel, or carbon steel

- Customizable work height, screen size, and discharge configuration

- Optional accessories: safety interlocks, drum hoists, or integrated sieving systems

- Various discharge connections: rotary valves, screw conveyors, or direct chutes

- Flexible integration with existing production lines and dust collection systems

contact us to get your solution for free!

Applications

Food & Pharmaceutical

- Milk powder, protein powders

- Flours, starch, sugar

- Vitamins, pharmaceutical powders

- Tea, spices, food additives

Chemicals & Plastics

- PVC, PE, PP plastic pellets

- Resins, polymers, compounds

- Catalysts, chemical powders

- Fertilizers, industrial chemicals

Minerals & Construction

- Cement, fly ash, limestone

- Sand, silica, clay powders

- Gypsum, plaster, dry mixes

- Ceramic powders, pigments

Recycling & Biomass

- Recycled plastic flakes

- Wood chips, biomass pellets

- Metal powders, recovered materials

- Activated carbon, filter media

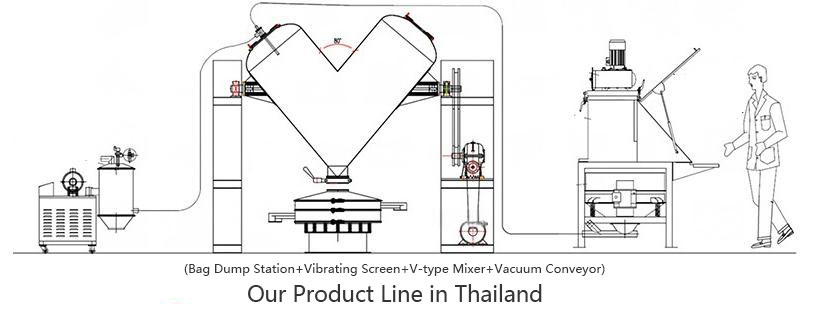

Explore Our Key Integration Examples

Our bag dump stations are expertly designed for automated feeding in a wide range of applications:

Technical Parameters

| Model | Screening area | Power (kW) | Speed (r/min) | Dynamic load | Static load | Excitation force | Flow rate (kN) | Wind pressure |

|---|---|---|---|---|---|---|---|---|

| HC-800 | 0.42 | 2×0.15 | 1460 | 500N | 1500N | 2.5×2 | 1550-997 | 1217-1641 |

| HC-1000 | 0.64 | 2×0.25 | 1460 | 800N | 2500N | 5×2 | 1550-997 | 1217-1641 |

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

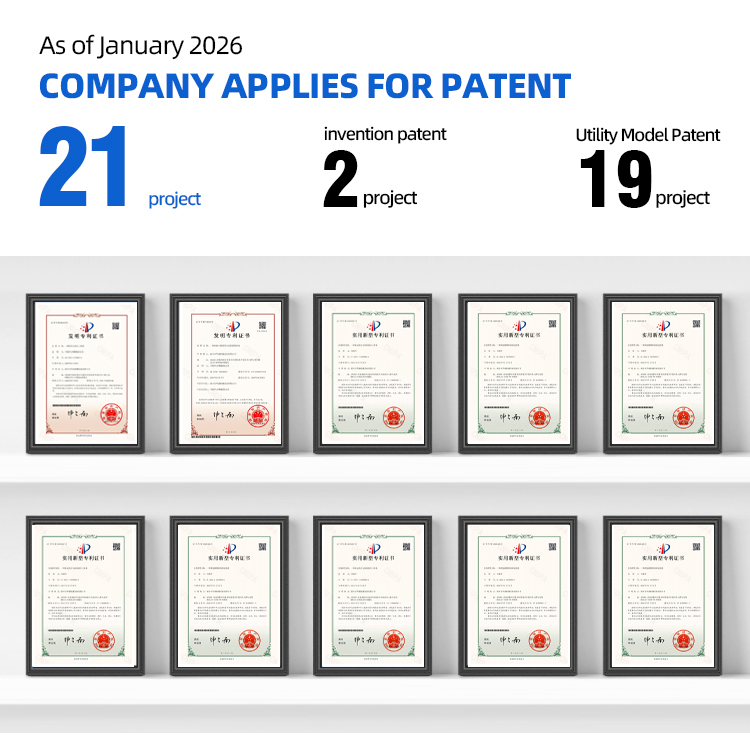

Company Strength