Henan Tianzhong Vibration Equipment Co.Ltd

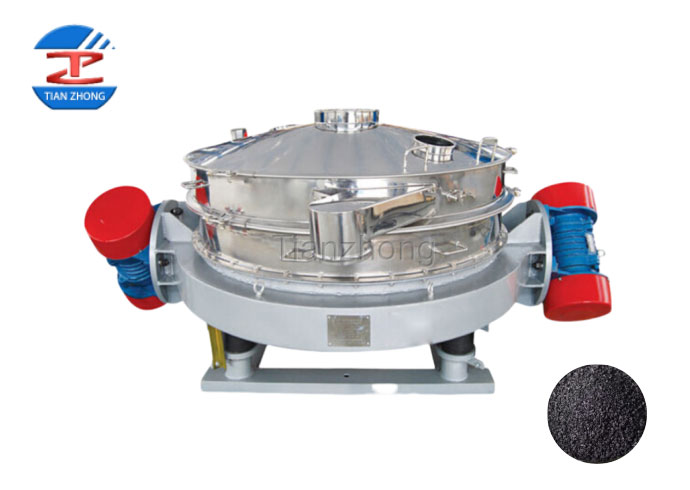

Direct Discharge Vibrating Screen

Boost output instantly with rapid, high-throughput screening built for continuous operation.

Country of Origin: Henan, China

Technical Parameters:

-

Screen Diameter: 600-1500 mm

-

Screen Mesh Size: 2-500 mesh or customized

-

Layers: 1-5 layers

-

Material: Stainless Steel , Carbon steel

Get a Fast Quote from the Manufacturer

- Reply within 12 hours

- Free technical advice

- No spam, no obligation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

What is direct discharge vibrating screen?

Direct discharge vibrating screen uses a single horizontal vibrating motor as the vibrating source, with the vibrating motor located on one side of the machine body. After entering the equipment, the material undergoes elliptical motion on the screen surface due to the force of the vibrating source. While rapidly and repeatedly completing the screening process, the vibrating force continuously and repeatedly exerts peeling, dispersing, and reorganisation effects on the material, enabling it to pass through the screen quickly. Material that cannot pass through the screen is discharged through the upper discharge port of the equipment according to its movement trajectory, completing the screening process.

The vibration source is available in single-motor and dual-motor configurations, with multiple adjustable material movement trajectories, significantly enhancing the equipment’s adaptability; direct material discharge enables higher processing capacity. It is widely used for coarse and precise screening of granular powders in industries such as flour, starch, laundry powder, metal powder, additives, chemicals, and non-metallic minerals, featuring high processing capacity and ease of integration with production lines. The screen size can be selected between 600 mm and 1800 mm.

Main Features

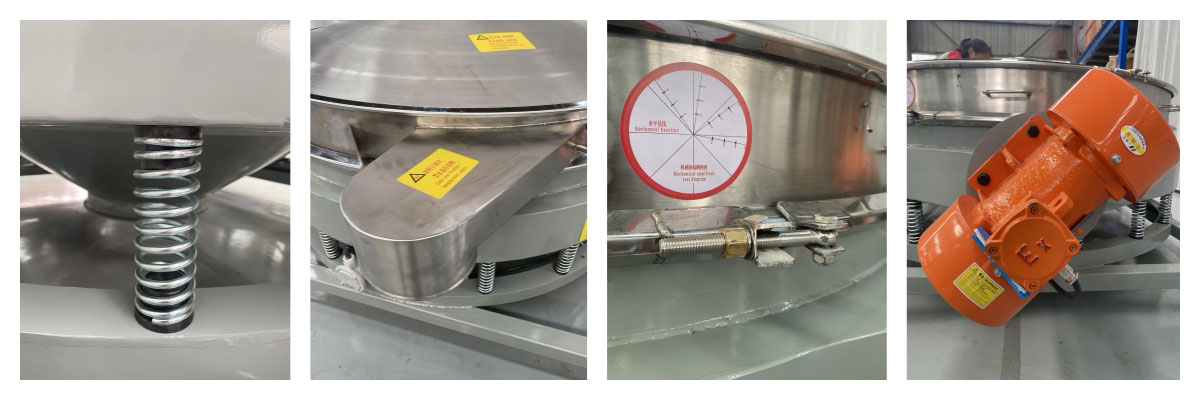

Performance Advantages

- Low energy consumption with high efficiency, designed for continuous 24-hour production

- Compact, space-saving design that’s easy to move, disassemble, and clean, meeting GMP standards

- Ultra-low noise design with a tight seal to prevent liquid leakage and dust emissions

Custom Options

- Available in single or multiple layers for customized screening efficiency

- Various bouncing ball materials and sizes, such as silicone and rubber

- Customizable sealing materials: silicone, rubber, PTFE, or high-temperature options

- Adjustable inlet/outlet direction and height for flexible production layout integration

Our engineers will recommend suitable machine models based on your specific usage requirements. We can also design production lines and provide engineering drawings. Please contact us with your detailed specifications.

Applications

Food & Beverages

- Flour, starch, milk powder

- Food additives, sugar, rice flour

- Fruit juice, egg powder, fish meal

- Condiments, soybean meal

Chemicals & Pharmaceuticals

- Carbon black, silica, kaolin

- Pharmaceutical powders, herbal powders

- Soda ash, resin powder

- Chemical fertilizers, pigments

Plastics & Rubber

- Polyethylene, resin powders

- Plastic pellets, PVC

- Recycled plastics, polymer granules

- Rubber powder/additives

Minerals & Recycling

- Quartz powder, feldspar powder

- mica, glass beads

- Metal powders

- fly ash, foundry sand

Technical Parameters

| Model | Power (KW) | Screen diameter (mm) | Effective area (m²) | Volume (L*W*H) |

|---|---|---|---|---|

| ZPS-600 | 0.12 | 520 | 0.2124 | 740×600×560 |

| ZPS-800 | 0.18 | 720 | 0.4072 | 1010×800×600 |

| ZPS-1000 | 0.25 | 890 | 0.6221 | 1200×970×640 |

| ZPS-1200 | 0.55 | 1090 | 0.9331 | 1430×1170×700 |

| ZPS-1500 | 0.75 | 1390 | 1.5175 | 1780×1470×760 |

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

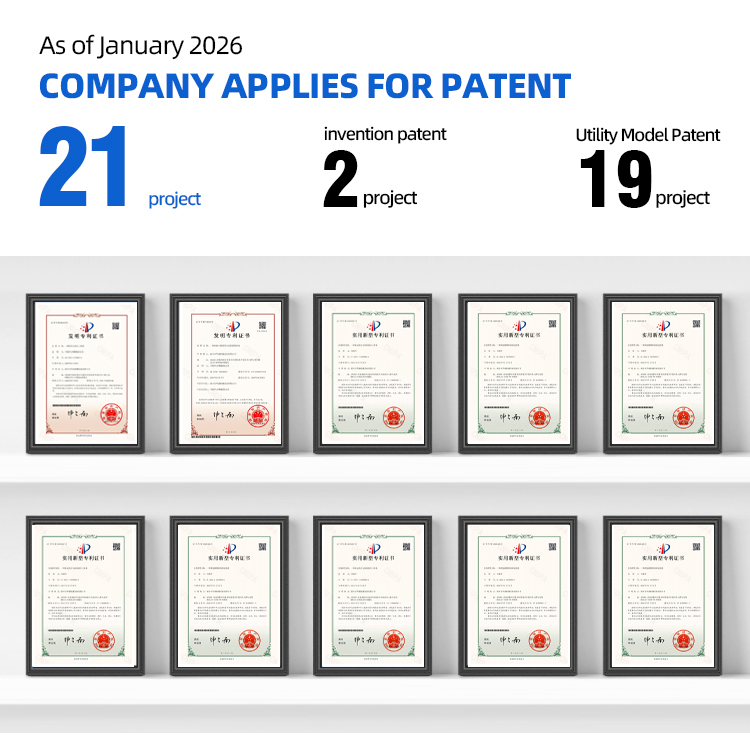

Company Strength