Henan Tianzhong Vibration Equipment Co.Ltd

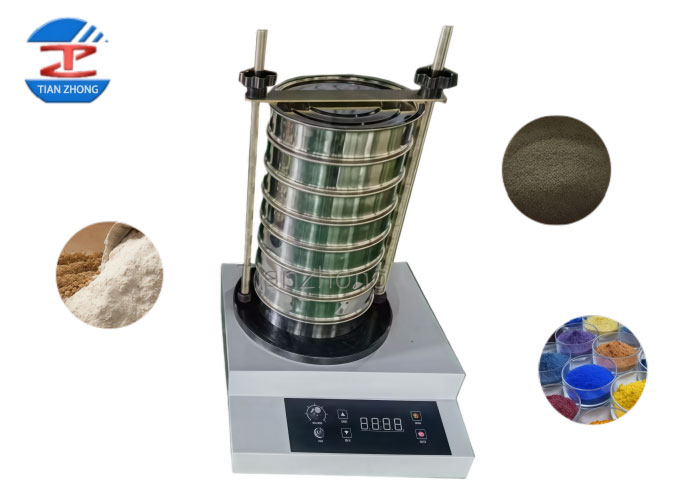

Lab Test Sieve Shaker

Ensuring reliable, repeatable laboratory particle analysis with controlled vibration.Offering stable, low-noise, high-frequency motion for precise lab-scale powder testing.

Country of Origin: Henan, China

Typical Specifications (Customizable):

-

Screen Diameter(mm): Based on different models

-

Screen Mesh Size(mesh): ≤1000

-

Layers: 1-8 layers

-

Material Types: Powder, Granules, Bulk Solids, liquid

Get a Fast Quote from the Manufacturer

- Reply within 12 hours

- Free technical advice

- No spam, no obligation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

What is Lab test sieve shaker?

The Lab Test Sieve Shaker is an advanced particle size analysis instrument designed to meet the rigorous demands of laboratory environments. It is ideal for precise and repeatable sieving of powders, granules, and suspensions. This versatile sieve shaker offers both mechanical and electromagnetic options to provide the highest accuracy and efficiency for various material testing applications.

Laboratory Vibrating Sieve

The Laboratory Vibrating Sieve utilizes mechanical vibration to ensure uniform particle separation and classification. It offers adjustable vibration intensity and frequency, making it suitable for both dry and wet sieving of a wide range of materials. This shaker is particularly effective for quality control, research, and material testing across industries like pharmaceuticals, chemicals, food, and materials science.

Electromagnetic Sieve

The Electromagnetic Sieve is a specialized variant of the lab sieve shaker, utilizing electromagnetic force to generate high-frequency vibrations. This allows for more precise and finer particle separation, especially for smaller samples or materials that require high precision. The electromagnetic system offers superior control over vibration frequency, ensuring high efficiency and minimal material loss during testing.

Main Features

Performance Advantages

- Compact design with high efficiency, capable of sieving powders up to 400 mesh

- Low-maintenance operation with no mechanical parts, making cleaning and screen replacement quick and easy

- Versatile functionality, perfect for powder separation, as well as mixing, granulation, and filtration applications

- Durable construction with stainless steel (304) components, ensuring long-lasting performance and resistance to corrosion

- Flexible design that accommodates a variety of laboratory setups and applications

Custom Options

- Choice of **mechanical** or **electromagnetic** models for optimal performance

- Optional **ultrasonic system** for efficient fine particle separation

- **Bouncing balls** available in various sizes and materials (silicone, rubber)

- Customizable seal materials (silicone, rubber, PTFE, or high-temperature options)

- Flexible inlet/outlet direction and height for easy integration into lab setups

Our engineers will recommend suitable machine models based on your specific usage requirements. We can also design production lines and provide engineering drawings. Please contact us with your detailed specifications.

Applications

Abrasives & Geology

- Grinding powders, abrasive materials

- Mineral samples, geological powders

- Sand, gravel, and soil analysis

- Metallurgical samples, ores

Metallurgy & Mining

- Metal powders, alloys

- Ore and mineral separation

- Mining products analysis

- Furnace dust, slag analysis

Pharmaceutical & Chemical

- Pharmacopoeia powders, excipients, API

- Chemical reagents and catalysts

- Formulation and particle size analysis

Chemical & Building Materials

- Cement, lime, and gypsum powders

- Building material additives

- Polymer compounds, resins

- Paints, pigments, and coatings

Technical Parameters

| Name | Numerical Value | Unit |

|---|---|---|

| Can Accommodate Sieve Diameter | Φ200/Φ100/Φ75 | mm |

| Screening Particle Size | 0.025~3 ↑ | mm |

| Noise | <50 | dB |

| Amplitude | 0~5 | mm |

| Vibration Frequency | 1400 | times/minute |

| External Dimension | 350: 380 300+N*50 | length, width, height |

| Power Supply | 220; 50 | V;Hz |

| Total Weight | 35 | kg |

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

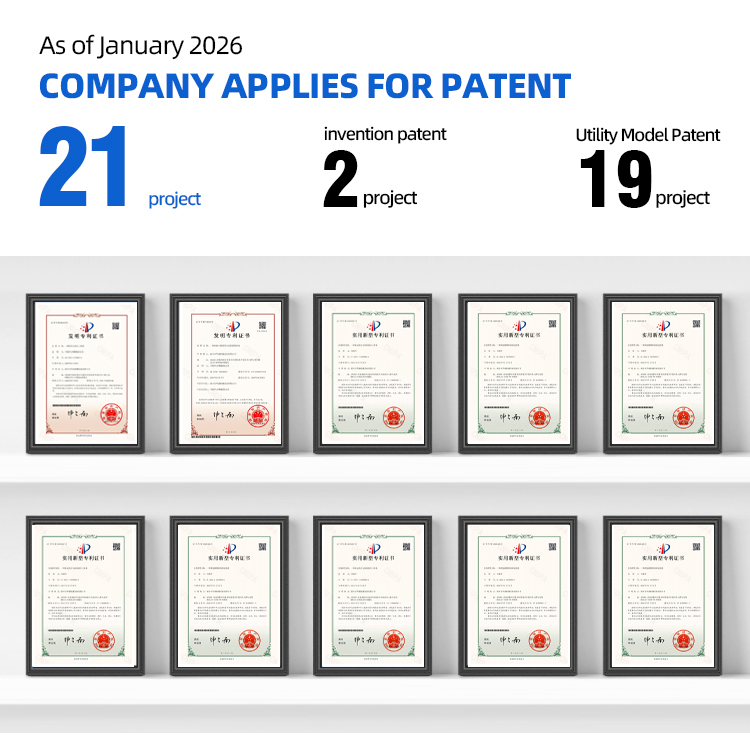

Company Strength