Henan Tianzhong Vibration Equipment Co.Ltd

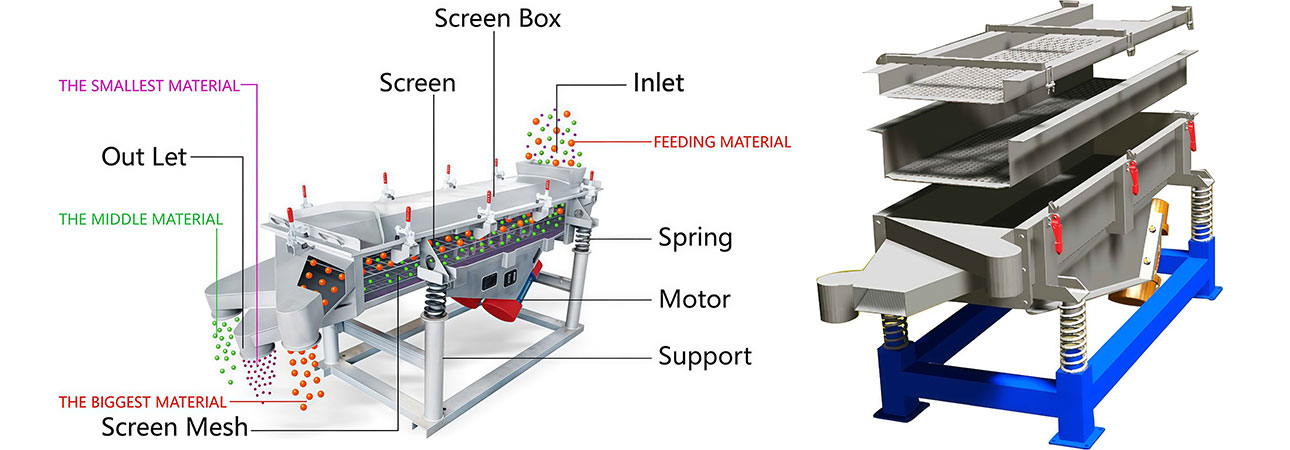

Linear Vibrating Screen

Engineered for high-capacity, precise particle & lumpy materials & liquids and mixtures of particles separation with stable, linear motion performance.

Country of Origin: Henan, China

Typical Specifications (Customizable):

-

-

Screen Length: 2000-6000 mm

-

Screen Width: 500-2200 mm

-

Screen Mesh Size: ≤500 mesh or≥0.028mm

-

Layers: 1-5 layers

-

Get a Fast Quote from the Manufacturer

- Reply within 12 hours

- Free technical advice

- No spam, no obligation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

What is Linear Vibrating Screen?

The linear vibrating screen utilizes the principle of vibration motor excitation to cause the material to be thrown up on the screen surface while moving forward in a straight line. Combined with appropriately matched screens, this achieves the purpose of screening.

Main Features

Performance Advantages

- The screen section design enables rapid screen changes and quick tensioning

- High efficiency with low noise levels

- Long material travel path for high screening accuracy and large capacity

- Adjustable deck spacing and angle based on particle size and throughput

Custom Options

- Optional dust cover, feeding hopper, and mobile base

- Carbon steel, 304, or 316L stainless steel construction

- Customized mesh sizes for different screening accuracy needs

- Single to multi-layer screen decks available

- Customizable shapes and structures can be designed according to specific production site requirements.

Our engineers will recommend suitable machine models based on your specific usage requirements. We can also design production lines and provide engineering drawings. Please contact us with your detailed specifications.

Applications

Food

- Sugar, salt, glucose, MSG, chicken essence,

- Bread crumbs, freeze-dried food, coconut granules

- Frozen dumplings

Chemical

- Sodium bicarbonate, fused silica powder

- Spherical silica powder, silica

- Refractory materials and industrial additives

Pharmaceutical

- Pellets, granular pills and tablets

- Traditional Chinese medicine pieces

- Herbal powder and fine pharmaceutical granules

Metal & Mining

- Iron powder, aluminum powder, lead powder

- Alloy powder, metallurgical powder

- Steel pellets, alumina, abrasive materials

Technical Parameters

| Model | Screen Size (mm) | Screen Inclination (°) | Layer Number | Power (kW) |

|---|---|---|---|---|

| DZSF530 | 500×3000 | 0–7 | 1–5 | 2× (1.1–1.5) |

| DZSF535 | 500×3500 | 0–7 | 1–5 | 2× (1.1–1.5) |

| DZSF1020 | 1000×2000 | 0–7 | 1–5 | 2× (0.75–1.1) |

| DZSF1025 | 1000×2500 | 0–7 | 1–5 | 2× (1.1–1.5) |

| DZSF1030 | 1000×3000 | 0–7 | 1–5 | 2× (1.5–2.2) |

| DZSF1035 | 1000×3500 | 0–7 | 1–5 | 2× 2.2 |

| DZSF1040 | 1000×4000 | 0–7 | 1–5 | 2× (2.2–3.0) |

| DZSF1225 | 1200×2500 | 0–7 | 1–5 | 2× (1.5–2.2) |

| DZSF1230 | 585×3000×2 | 0–7 | 1–5 | 2× (2.2–3.0) |

| DZSF1235 | 585×3500×2 | 0–7 | 1–5 | 2× (2.2–3.0) |

| DZSF1535 | 735×3500×2 | 0–7 | 1–5 | 2× (2.2–3.0) |

| DZSF1540 | 735×4000×2 | 0–7 | 1–5 | 2× (3.0–4.0) |

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

Company Strength