Henan Tianzhong Vibration Equipment Co.Ltd

Ribbon Mixer

Deliver fast, uniform powder blending at scale with powerful, high-efficiency ribbon mixing technology.

Country of Origin: Henan, China

Technical Parameters:

-

Rotational Speed: 14-100 r/min

-

Weight: 550-8200 kg

-

Capacity: Customers’ Request

Get a Fast Quote from the Manufacturer

- Reply within 12 hours

- Free technical advice

- No spam, no obligation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

What is ribbon mixer?

The ribbon mixer is a highly efficient, versatile batch mixing equipment for dry powders or granular materials. Its core feature lies in the unique ribbon-shaped agitator within the mixing chamber. Through gentle yet effective shear and convection actions, it achieves rapid and uniform blending of materials with varying densities and particle sizes. It stands as one of the most common and reliable mixing devices across industrial sectors including chemical, food, pharmaceutical, and plastics.

Main Features

Performance Advantages

- Gentle mixing prevents material damage

- Fast, homogeneous blending

- Complete discharge with minimal residue

- Low maintenance and durable construction

Custom Options

- Single or double ribbon design

- Carbon steel or stainless steel

- Multiple discharge valve options

- Heating/cooling jackets available

contact us to get your solution for free!

Applications

Food & Bakery

- Dough, batter, icing

- Chocolate, butter, margarine

- Meat paste, sausage filling

Chemicals & Adhesives

- Paints, coatings, pigments

- Sealants, adhesives, putty

- Thick paste chemicals

Pharmaceuticals & Cosmetics

- Creams, ointments, lotions

- Toothpaste, shampoo paste

- Cosmetic foundations

Building Materials

- Ceramic tile adhesive

- Grout, mortar mix

- Thick slurry compounds

Technical Parameters

| Mixer model | L | D | H | Rotational speed | Equipment weight |

|---|---|---|---|---|---|

| mm | mm | mm | r/min | kg | |

| WLDH-0.3 | 1900 | 1000 | 950 | 100 | 550 |

| WLDH-0.5 | 2250 | 1150 | 1250 | 100 | 900 |

| WLDH-1 | 2650 | 1300 | 1400 | 85 | 1500 |

| WLDH-2 | 3055 | 1440 | 1640 | 63 | 2500 |

| WLDH-3 | 3560 | 1560 | 1980 | 63 | 3600 |

| WLDH-5 | 4170 | 1600 | 2075 | 56 | 5100 |

| WLDH-6 | 4730 | 1900 | 2200 | 56 | 5600 |

| WLDH-8 | 5100 | 2050 | 2300 | 41 | 6500 |

| WLDH-10 | 5725 | 2150 | 2500 | 34 | 7800 |

| WLDH-12 | 6800 | 2200 | 2600 | 22 | 8200 |

| WLDH-15 | 7100 | 2500 | 2900 | 14 | — |

| WLDH-20 | 7400 | 2700 | 3150 | 14 | — |

Note: Due to product improvements or customer customization, if the table parameters are different from the actual product, the actual product shall prevail.

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

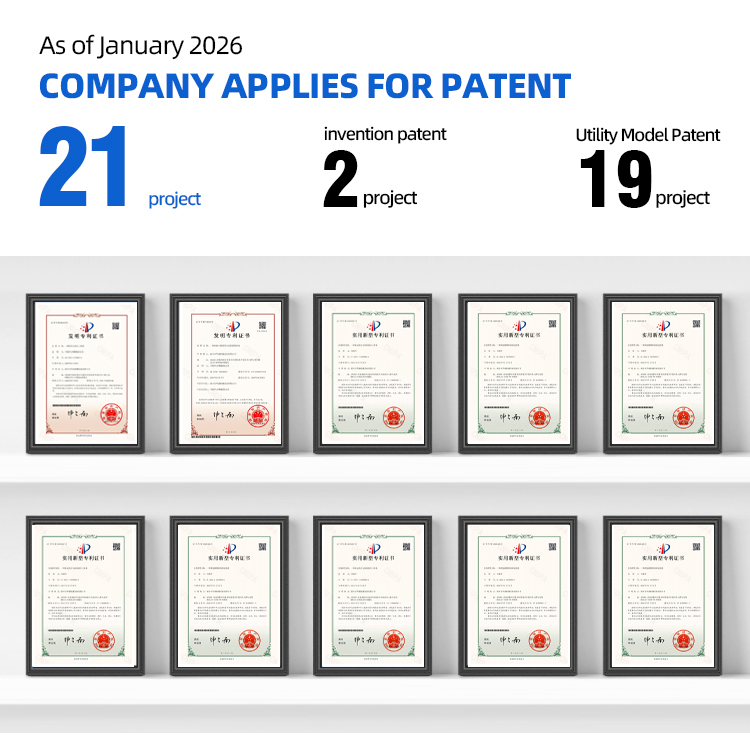

Company Strength