Henan Tianzhong Vibration Equipment Co.Ltd

Rotary Vibrating Screen

Designed for food, chemical and pharmaceutical production lines.Suitable for flour, starch, spice, sugar and fine powder materials.

Why Choose This Rotary Vibrating Screen

- Strong ability: Can sieve any powder down to 600 mesh(0.02mm), and filter mucus up to 5 microns

- High efficiency: 1 to 5 layers of sieves can be used to sort two to six particle size at the same time

- Custom screen size & mesh based on your material

Get a Fast Quote from the Manufacturer

- Reply within 12 hours by engineer

- Free technical advice & mesh suggestion

Direct Manufacturer · Custom Solutions · CE & ISO Certified

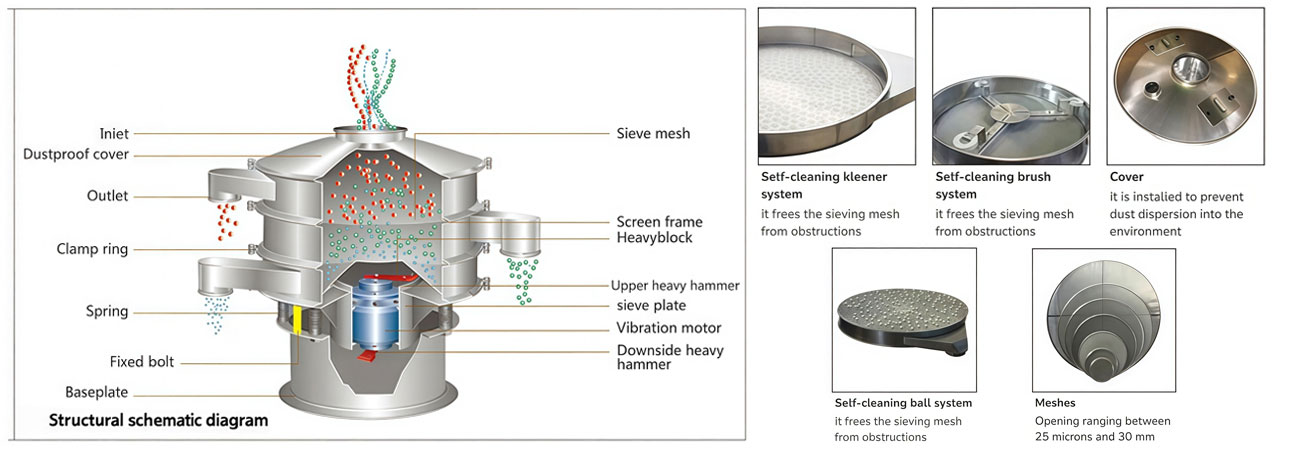

What is Rotary Vibrating Screen?

A rotary vibrating screen is a high-efficiency screening machine used to separate powder, granule, and liquid materials with high accuracy.It is widely applied in food, chemical, pharmaceutical, and industrial production lines to remove impurities, classify materials by size, and improve product consistency.

Compared with traditional screening equipment, rotary vibrating screens offer higher screening precision, stable operation, and flexible configuration, making them ideal for continuous industrial use.

- Suitable for fine powder to granules

- Supports dry and wet screening

- Customizable screen diameter, mesh size, and layers

🔹 Not sure if this screen suits your material? Our engineers can help you select the right configuration.

Applications

Chemical

- Resins, industrial chemicals

- Cosmetics, pigments, paints

- Various chemical powders and liquids

Food

- Sugars, starches, salt

- Rice flour, milk powder, egg powder

- Soy sauce, soy milk, fruit juices

Metals & Mining

- Aluminum, lead, copper powders

- Alloy & welding rod powder

- Quartz sand, alumina, kaolin

Other Industries

- Waste oil, wastewater

- Papermaking pulp,additives

- Activated carbon and related materials

Different materials require different mesh sizes and configurations.

Our engineers recommend suitable models based on your material.

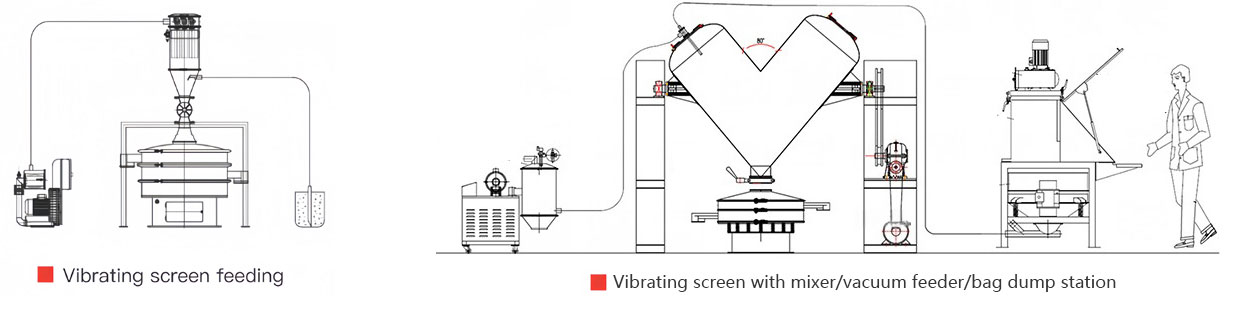

Explore Our Key Integration Examples

Our rotary vibrating screen are expertly designed for screening in a wide range of applications:

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

Main Features

Performance Advantages

- Screening accuracy with precision up to 500 mesh and over 95% efficiency

- Enhanced material fluidity and permeability for significantly higher screening output

- Excellent anti-blocking performance with optional ultrasonic system to keep mesh clean

- Compact and fully enclosed design to prevent dust leakage

- Low noise, small footprint, and easy to move or maintain

Custom Options

- 1–5 screen layers available to meet different screening requirements

- Bouncing ball material options: silicone, rubber

- Materials optional:contact stainless steel,all-stainless steel,all-carbon steel

- Seal types customizable: food-grade silicone, rubber, or PTFE

- Custom inlet/outlet design to fit your production layout

Technical Parameters

| Model | Power (kW) | Screen Diameter (φ) | Volume (mm) | Number of Layers |

|---|---|---|---|---|

| HC-400 | 0.18 | 320mm | 580 × 580 × 560 | 1~3 |

| HC-600 | 0.37 | 550mm | 800 × 800 × 680 | 1~3 |

| HC-800 | 0.55 | 750mm | 900 × 900 × 780 | 1~3 |

| HC-1000 | 0.75 | 950mm | 1160 × 1160 × 880 | 1~3 |

| HC-1200 | 1.5 | 1150mm | 1360 × 1360 × 980 | 1~3 |

| HC-1500 | 2.5 | 1450mm | 1850 × 1850 × 1130 | 1~3 |

| HC-1800 | 3.7 | 1750mm | 2200 × 2200 × 1360 | 1~3 |

Company Strength