Henan Tianzhong Vibration Equipment Co.Ltd

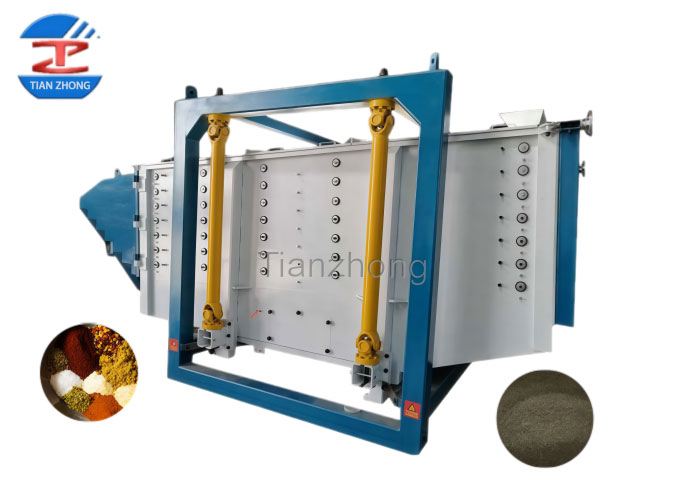

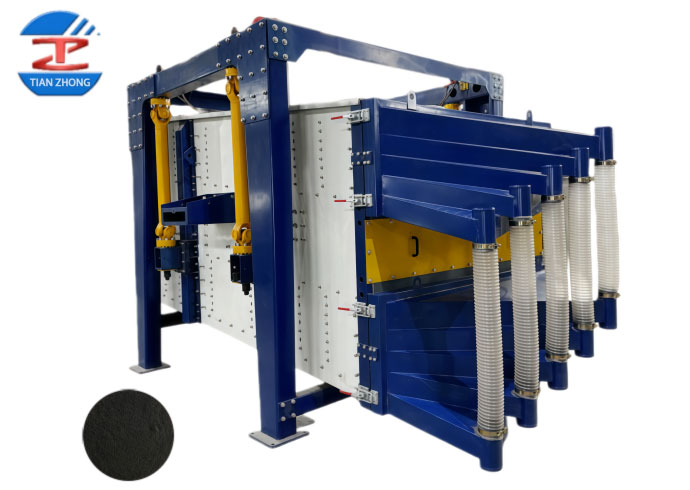

Square Tumbler Screen

Deliver superior screening precision and massive capacity—ideal for strict quality control applications.

Country of Origin: Henan, China

Typical Specifications (Customizable):

-

Effective screening area: 3-7.2 m2

-

Capacity: 501-1000 l/h

-

Layers: 1-8 layers

-

Material Types: Powder, Granules, Bulk Solids, liquid

Get a Fast Quote from the Manufacturer

- Reply within 12 hours

- Free technical advice

- No spam, no obligation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

What is Square tumbler screen?

The square tumbler screen series is a screening equipment designed to meet the demands of large-capacity, high-precision applications. Featuring a large screening area and a long operational trajectory, it is typically configured with 3-4 layers but can be customized to client-specified dimensions. It is widely used in industries such as chemical , metallurgy, non-ferrous metals, ferrous metals, food , and abrasives.

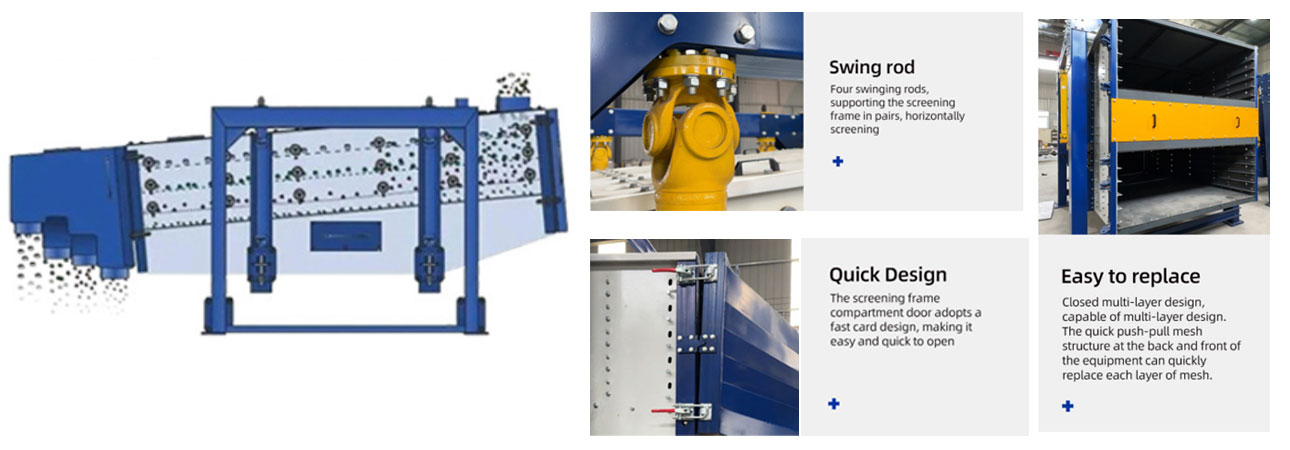

Main Features

Performance Advantages

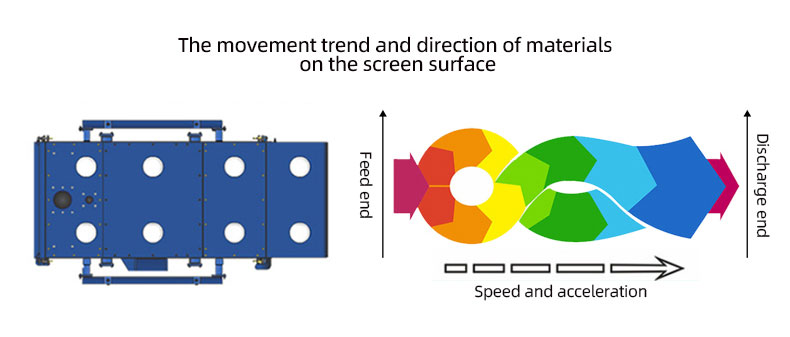

- Combines circular, elliptical, and linear motion for superior screening of diverse materials

- Excellent self-cleaning performance with high screen utilization and efficiency

- Reciprocating rotary motion rapidly disperses and screens powders or irregular particles

- Compact and durable design ensures extended screen lifespan with minimal vibration

- Superior sealing prevents dust dispersion and operates with low noise levels

Custom Options

- 1–8 screen layers available for multi-grade precision classification

- Various anti-blocking systems: bouncing balls, ultrasonic devices, or rotating brushes

- Multiple sealing materials: silicone, rubber, PTFE, or high-temperature resistant options

- Customizable screen frame dimensions and mesh specifications

- Flexible inlet/outlet configurations to adapt to different production layouts

Our engineers will recommend suitable machine models based on your specific usage requirements. We can also design production lines and provide engineering drawings. Please contact us with your detailed specifications.

Applications

Food & Beverages

- Milk powder, sugar, starch

- Citric acid, spices, tea

- Flours, feed

- Vitamins, herbal powders

Chemicals & Pharmaceuticals

- Resins, PVC, EPS, PVI

- Chemical fertilizers,plastics

- Pharmaceutical powders

- Polymers, catalysts

Plastics & Rubber

- Plastic pellets, PVC

- Rubber powder, resin, additives

- Polymer granules, compounds

- Recycled plastic materials

Renewable Resources

- Recycled plastics, EPS foam

- Wood and biomass pellets

- Metal powder recovery

- Activated carbon,fine powders

Technical Parameters

| Model | Screening area | Power | Screening angle | Layers | Rotating frequency | Screen box distance |

|---|---|---|---|---|---|---|

| FYB1536 | 5.4 m² | 5.5 KW | 5° | 1~5 | 180~264 r/min | 25~60 mm |

| FYB2036 | 7.2 m² | 7.5 KW | 5° | 1~5 | 180~264 r/min | 25~60 mm |

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

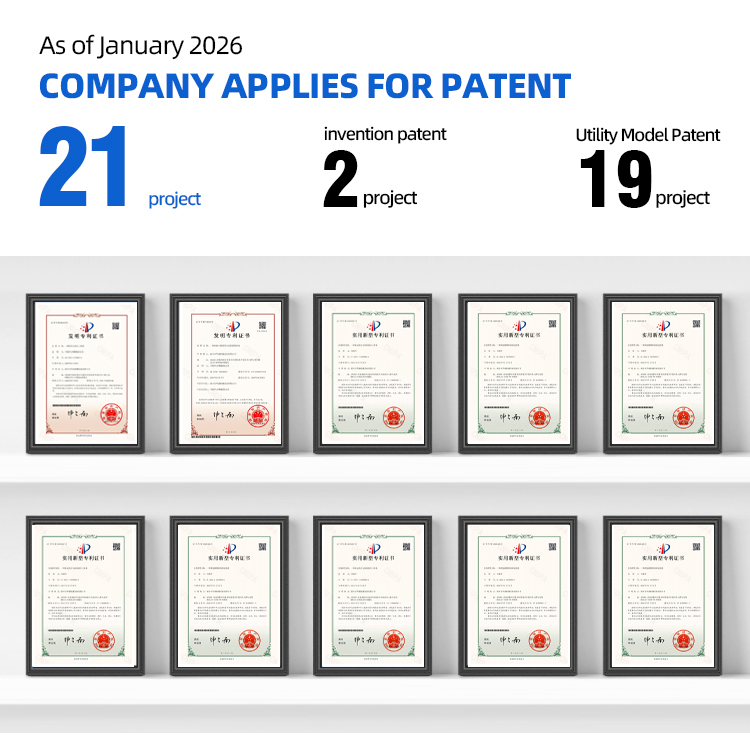

Company Strength