Henan Tianzhong Vibration Equipment Co.Ltd

Tumbler Screening Machine

Providing gentle, high-efficiency screening for fragile or irregular particles.

Country of Origin: Henan, China

Typical Specifications (Customizable):

-

Screen Diameter: 400–2000 mm (16–78 in)

-

Screen Mesh Size: 2-500 mesh or customized

-

Layers: 1-5 layers

-

Material Types: Powder, Granules, Bulk Solids, liquid

Get a Fast Quote from the Manufacturer

- Reply within 12 hours

- Free technical advice

- No spam, no obligation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

What is tumbler screening machine?

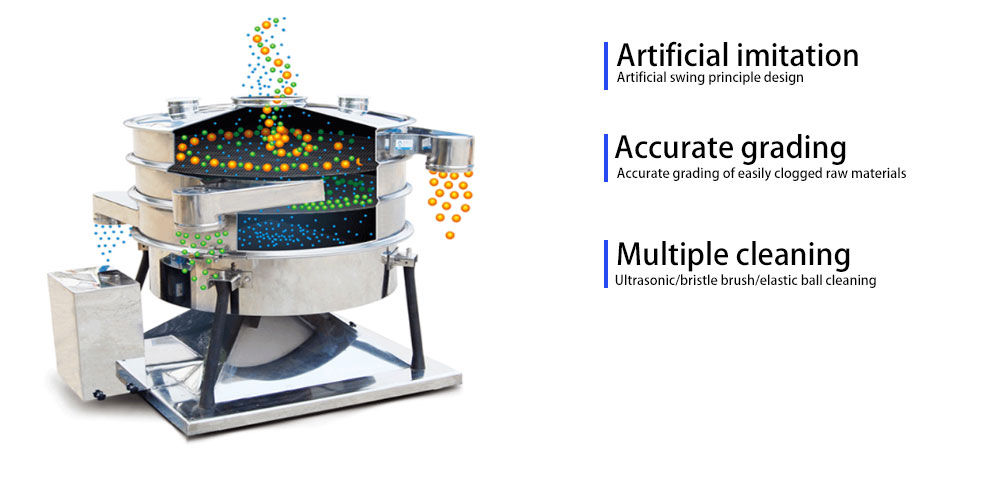

The tumbler screening machine is a highly efficient screening machine specially designed to meet the needs of manufacturers requiring high-volume, high-precision screening. The simplest form of screening involves using both eyes to observe while manually sifting with both hands. The tumbler screening machine is a mechanical simulation of this process, effectively replicating the principles of manual screening motion. It is suitable for all types of fine and ultra-fine powders and granular materials, particularly those that are difficult to handle.The working principle is as follows:

1. The basic rotational motion is similar to manual screening. The eccentricity is adjustable from 25 to 40 mm, and the low-speed V-belt speed is adjustable from 120 to 360 rpm.

2. The dwell time for each product can be adjusted by altering the radial and angular orientation of the swing screen relative to the drive shaft axis.

3. This creates a three-dimensional rolling motion combining horizontal and vertical movements. Material is uniformly distributed across the entire screen surface from the centre to the outer edge, propagating axially in a spiral motion, thereby completing the screening process for fine particles.

4. Horizontal and vertical acceleration increases with particle movement, enabling particles close to the sieve aperture size are successfully separated.; larger particles are transported to the outlet, where flow is controlled by an adjustable guide device, which is another factor influencing material residence time.

5. This process is repeated between screening layers.

Main Features

Performance Advantages

- Imitates manual sieving motion for ultra-gentle screening and minimal material damage

- Ideal for irregular, fragile, and easily broken particles with high screening accuracy

- Up to 5 times higher output compared to conventional vibrating screens

- Low acceleration design reduces mesh wear and extends service life

- Fully enclosed operation to eliminate dust leakage and keep the environment clean

Custom Options

- 1–5 screen layers available for multi-grade precision screening

- Anti-blocking devices optional: bouncing balls, ultrasonic system, rotating brushes

- Bouncing balls in various sizes and materials, such as silicone and rubber.

- Custom seal materials: silicone, rubber, PTFE, or high-temperature options

- Flexible inlet/outlet direction and height to match production layout

Our engineers will recommend suitable machine models based on your specific usage requirements. We can also design production lines and provide engineering drawings. Please contact us with your detailed specifications.

Applications

Food & Beverages

- Milk powder, sugar, starch

- Citric acid, spices, tea

- Flours, feed

- Vitamins, herbal powders

Chemicals & Pharmaceuticals

- Resins, PVC, EPS, PVI

- Chemical fertilizers,plastics

- Pharmaceutical powders

- Polymers, catalysts

Plastics & Rubber

- Plastic pellets, PVC

- Rubber powder, resin, additives

- Polymer granules, compounds

- Recycled plastic materials

Renewable Resources

- Recycled plastics, EPS foam

- Wood and biomass pellets

- Metal powder recovery

- Activated carbon,fine powders

Technical Parameters

| Model | Screening diameter (mm) | Screening area (m²) | Screen angle (°) | Layer number (s) | Power (kW) |

|---|---|---|---|---|---|

| GFBD-600 | Φ560 | 0.25 | 0-10 | 1-5 | 0.75 |

| GFBD-1000 | Φ930 | 0.68 | 0-10 | 1-5 | 1.1 |

| GFBD-1200 | Φ1130 | 1 | 0-10 | 1-5 | 1.5 |

| GFBD-1600 | Φ1530 | 1.84 | 0-10 | 1-5 | 4 |

| GFBD-2000 | Φ1920 | 2.9 | 0-10 | 1-5 | 5.5 |

| GFBD-2400 | Φ2350 | 4.31 | 0-10 | 1-5 | 5.5 |

| GFBD-2600 | Φ2350 | 5.03 | 0-10 | 1-5 | 5.5 |

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

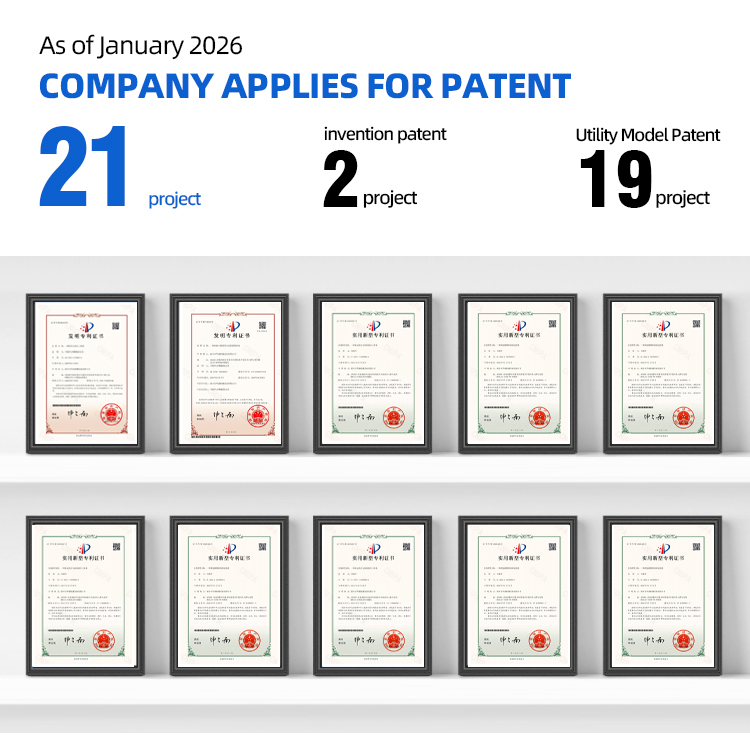

Company Strength