Henan Tianzhong Vibration Equipment Co.Ltd

Vacuum Conveyor

Designed for food, chemical, pharmaceutical and battery material production lines.Suitable for flour, sugar, milk powder, plastic pellets and fine powders.

Why Choose This Vacuum Conveyor

- Clean & dust-free conveying, improve workshop environment

- Flexible layout, easy integration with sieves, mixers & packing machines

- Custom design based on your material, capacity and distance

- High efficiency: Reduce labor intensity and improve work efficiency

Get a Fast Quote from the Manufacturer

- Reply within 12 hours by engineer

- Free technical advice & model recommendation

Direct Manufacturer · Custom Solutions · CE & ISO Certified

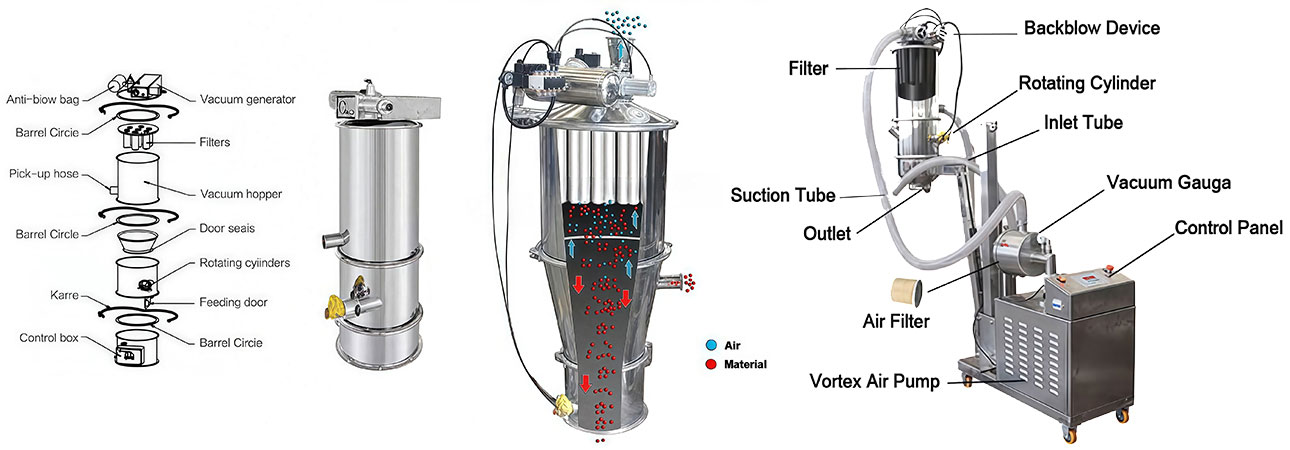

What is Vacuum Conveyor?

A vacuum conveyor is an automatic material conveying system that uses negative pressure to transfer powder, granules, and bulk solids in a closed pipeline.It is widely used in production lines where dust control, hygiene, and efficiency are critical, such as food processing, pharmaceuticals, chemicals, and battery materials.

Compared with traditional mechanical conveyors, vacuum conveyors offer clean operation, flexible layout, and low material loss, making them ideal for modern automated factories.

- Closed conveying, no dust leakage

- Gentle transfer, protect fragile materials

- Easy integration with mixers, sieves, and packaging machines

👉 Not sure if vacuum conveying is suitable for your material?

Applications

Food

- Flour, sugar, starch

- Milk powder, cocoa powder

- Protein powder, yeast

Chemical

- Plastic powder, resin

- PVC, PE, PP

- Carbon black, pigments

Pharmaceutical

- API powder

- Granules and tablets

- Herbal powder

Metal Powders

- Iron powder, aluminum powder

- Metal alloys, welding powder

- Additives, abrasives

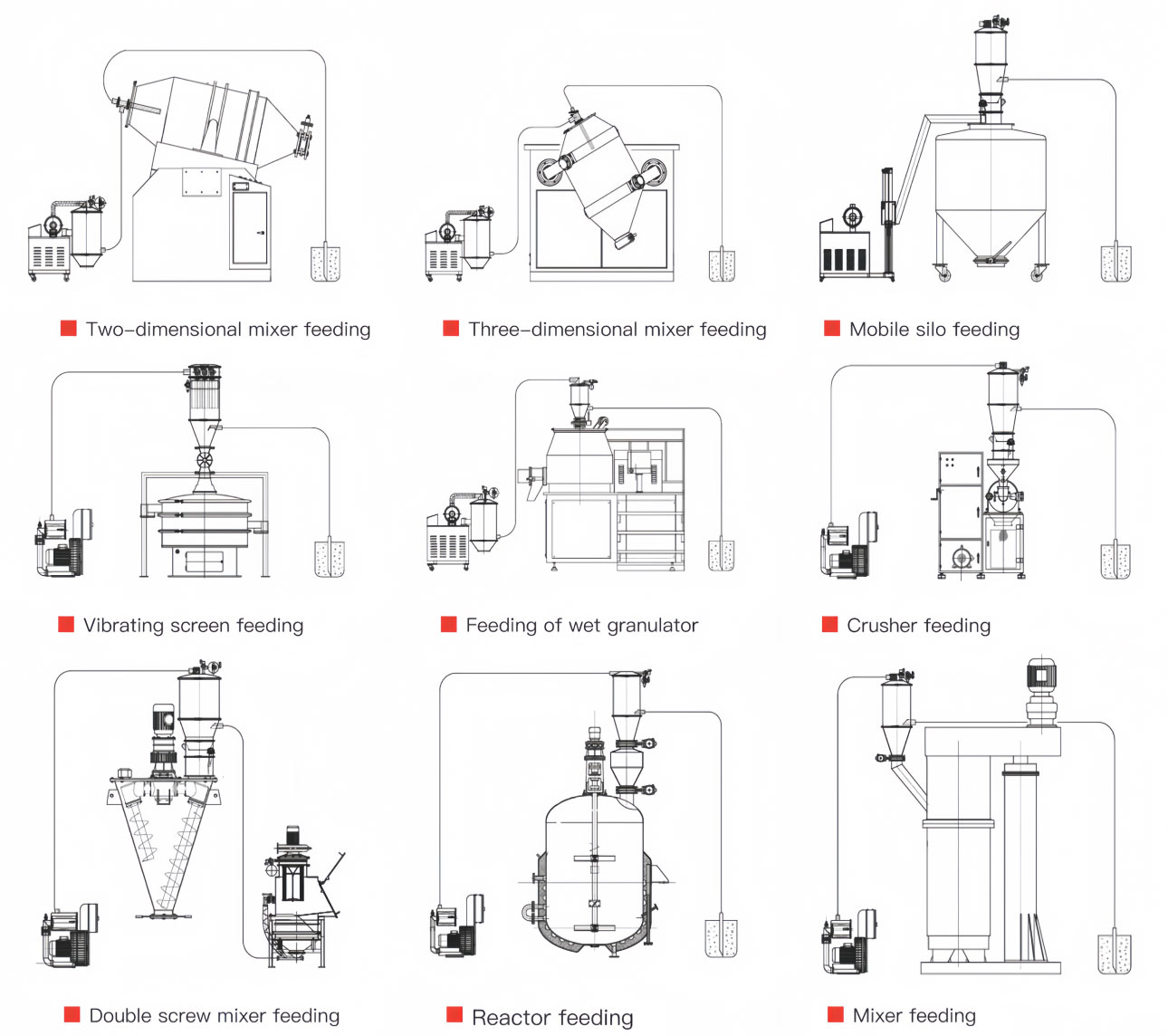

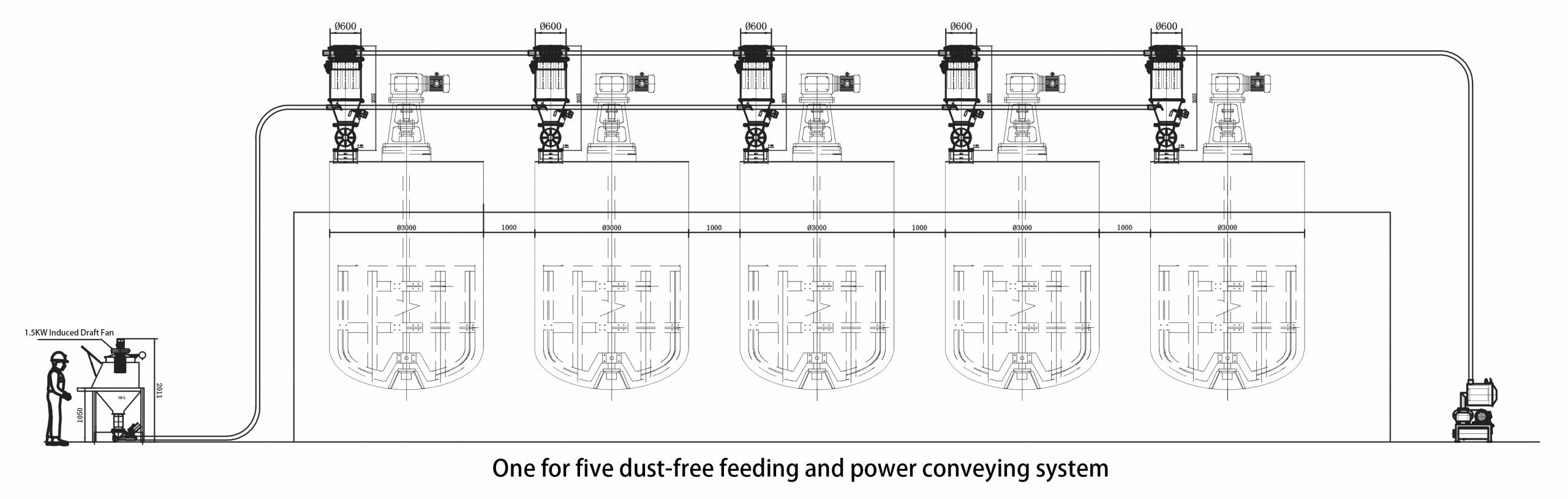

✔The vacuum feeder can convey materials dust-free for storage silos, mixers, screening machines, packaging machines, reactors, etc, so as to realize the seamless transfer of powder and granular materials.

Explore Our Key Integration Examples

Our vacuum conveyors are expertly designed for automated feeding in a wide range of applications:

Customer Site

From concept to production, we prioritize project profitability and balance complexity and feasibility in the design. From process and equipment audits, to getting your equipment running in optimal condition and retrofitting custom solutions, we can do it all.

contact us to get your solution for free!

Product Showcase

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992

Main Features

Performance Advantages

- Designed for clean, efficient, and automated powder conveying

- Fully enclosed system eliminates dust and contamination risks

- High conveying capacity with stable, continuous performance

- Compact, modular structure for easy installation and quick cleaning

- Conveying various materials,reduce labor intensity.

Custom Options

- Various models and capacities available for different applications

- Pneumatic or electric vacuum system optional

- Explosion-proof and food-grade finishes available

- 304/316L stainless steel construction for hygiene and durability

- Custom-built solutions to meet your specific conveying requirements

contact us to get your solution for free!

Technical Parameters

| Model | Motor Power (kW) | Conveying Capacity (kg/h) |

|---|---|---|

| HCSL-1 | 1.5 | 400 |

| HCSL-2 | 2.2 | 600 |

| HCSL-3 | 3.0 | 1200 |

| HCSL-4 | 5.5 | 2500 |

| HCSL-6 | 5.5 | 3200 |

| HCSL-7 | 7.5 | 6000 |

| HCSL-10-6 | 7.5 | 6000 (when the conveying distance is 10m) |

| HCSL-20-5 | 11 | 5000 (when the conveying distance is 20m) |

Note:Conveying capacity is measured with a 4-meter-long conveying pipe and flour as the material. The longer the conveying pipe, the lower the conveying capacity will be, and conveying capacity is also significantly influenced by the characteristics of the material.

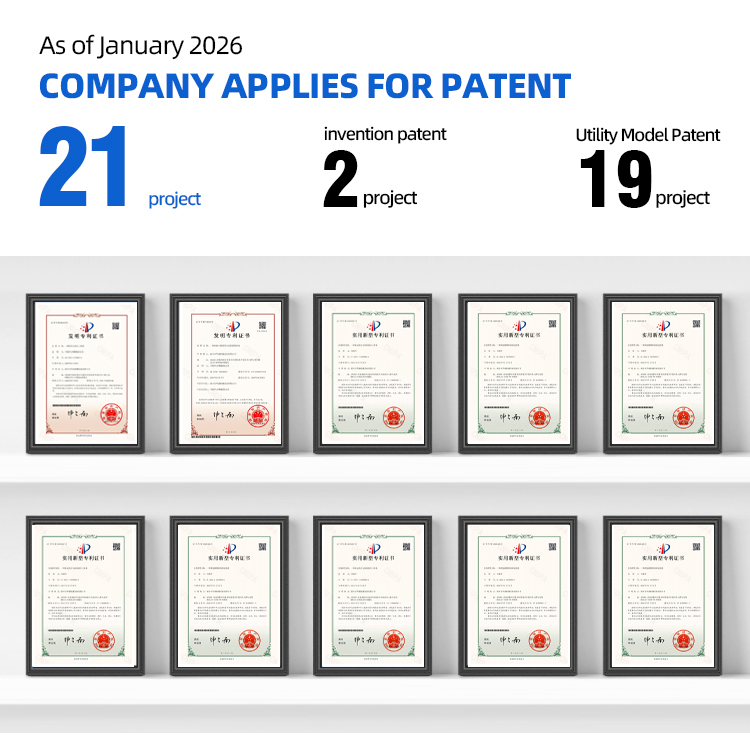

Company Strength