Henan Tianzhong Vibration Equipment Co.Ltd

Tea Handling & Processing Solution

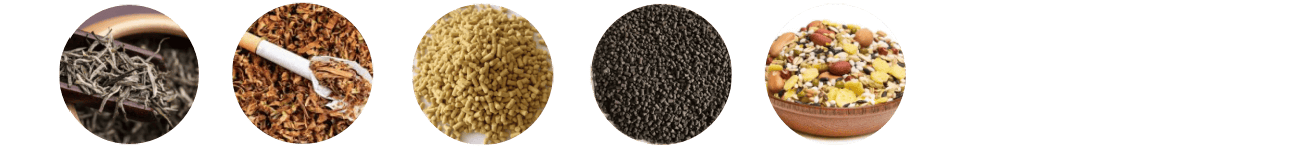

Tea leaves require gentle handling to prevent crushing and contamination during the processing stages. Our system provides solutions for bag unloading, sieving, blending, and transportation, ensuring the preservation of product quality.

Recommended Equipment

- Automatic bag opening and unloading system

- Vibrating sieve for particle separation

- Horizontal blender for uniform mixing

- Vacuum conveyor for sealed material transfer

Key Benefits

- Gentle handling to preserve leaf integrity

- Eliminates contamination risks during transport

- Ensures uniform mixing for consistent flavor

Tobacco Processing & Handling Solution

Tobacco processing involves multiple stages, including bagging, sieving, mixing, and conveying. Our equipment ensures a smooth and efficient flow from the unloading stage to packaging while preserving the quality of the tobacco.

Recommended Equipment

- Bag dump station for easy material unloading

- Vibrating sieves for particle classification

- Ribbon mixer for homogenous blending

- Pneumatic conveyor for dust-free transfer

Key Benefits

- Efficient and gentle handling of tobacco

- Prevents contamination during the processing stages

- Supports high throughput and continuous production

Feed Processing & Mixing Solution

Animal feed must be processed and mixed uniformly to ensure nutritional consistency. Our systems provide efficient and hygienic solutions for material unloading, sieving, mixing, and conveying in feed production.

Recommended Equipment

- Automatic bag opening station for easy material feeding

- Rotary sieve for uniform particle separation

- Horizontal feed mixer for thorough mixing

- Flexible screw conveyor for material transfer

Key Benefits

- Ensures uniform blending of feed ingredients

- Prevents contamination and retains nutritional value

- Optimizes production efficiency with minimal downtime

Fertilizer Mixing & Conveying Solution

Fertilizer production requires precise mixing, sieving, and transfer to ensure product uniformity and prevent contamination. Our systems ensure efficient processing from raw material unloading to final packaging.

Recommended Equipment

- Bag opening and unloading system

- Rotary sieve for removing impurities

- Horizontal mixer for homogeneous blending

- Conveyor systems for safe, dust-free material transfer

Key Benefits

- Ensures precise mixing and product uniformity

- Prevents cross-contamination during the process

- Minimizes dust exposure for cleaner working environments

Grain Handling & Sorting Solution

Grain processing requires efficient sorting, cleaning, and blending to ensure high-quality yield. Our equipment provides solutions for unloading, sieving, mixing, and conveying various types of grains for milling and packaging.

Recommended Equipment

- Automatic grain unloading and bagging station

- Grain cleaning and sorting sieve

- Ribbon mixer for even blending

- Flexible screw conveyor for grain transfer

Key Benefits

- Enhances the quality and consistency of grains

- Prevents contamination during handling and transfer

- Boosts operational efficiency with continuous processes

These products may also be suitable for you

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992