Henan Tianzhong Vibration Equipment Co.Ltd

Aluminum Powder Sieving & Conveying Solution

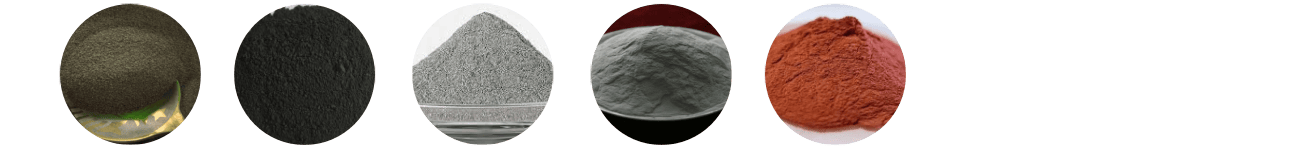

Aluminum powder is highly reactive and needs to be handled with care to avoid contamination and ensure uniform particle size. Our system provides dust-free handling and precise sieving for high-quality aluminum powder.

Recommended Equipment

- Rotary vibrating screen for precise particle separation

- Vacuum conveyor for sealed, dust-free transfer

- Ultrasonic vibrating screen for fine powder sieving

Key Benefits

- Prevents contamination of aluminum powder

- Ensures uniform granule size for consistent product quality

- Fully sealed system eliminates dust and material loss

Stainless Steel Powder Sieving & Conveying Solution

Stainless steel powder is widely used in additive manufacturing and metallurgy. Efficient sieving and dust-free handling are essential to maintain powder purity and ensure uniform distribution for sintering and 3D printing processes.

Recommended Equipment

- High-frequency vibrating screen for fine powder classification

- Vacuum conveyor for dust-free material transfer

- Automatic dust collection system for high-volume production

Key Benefits

- Maintains powder purity and prevents contamination

- Enhances powder flowability for additive manufacturing

- Stable, continuous processing with minimal downtime

Copper Powder Sieving & Conveying Solution

Copper powder is used extensively in electrical and manufacturing industries. Its handling requires precise sieving and smooth transfer to avoid agglomeration and ensure optimal flow properties for downstream processes.

Recommended Equipment

- Ultrasonic vibrating screen for fine copper powder separation

- Vacuum conveyor for dust-free handling

- Dust-free material feeding system for clean transfer

Key Benefits

- Prevents powder agglomeration and ensures uniform particle size

- Prevents contamination and maintains high-quality copper powder

- Efficient and dust-free transfer with minimal product loss

These products may also be suitable for you

Give us a email or Simply Complete the Form

Address:Xinxiang City, Henan Province, ChinaEmail:admin@hntzs.comWhatsApp:+86 18937322992Phone:+86 18937322992